Article

Complete guide to the thermoforming process

The world of manufacturing is constantly seeking solutions that enable the production of increasingly high-performance products while maximising the efficiency of the value chain. In this context, the thermoforming process is emerging as a key technique for applying plastic films to various substrates.

Among coating technologies, thermoforming represents an innovative method in which a plastic sheet is heated until flexible, allowing it to be shaped into precise forms that adhere closely to the underlying materials, such as MDF panels.

Naturally, not all solutions are equal, and increasing efficiency and quality in production lines first means understanding the complexities of the thermoforming process, then choosing the machines that best meet the specific needs of the company and its customers.

This guide aims to provide a comprehensive overview of the process, its variations, and the benefits it can offer today to companies operating in various manufacturing sectors.

Overview of the thermoforming process

The thermoforming process plays a crucial role in modern industry, especially in sectors where aesthetics and durability are key success factors for business development.

By using heat to soften plastic sheets, manufacturers can create complex and customised designs that enhance the visual appeal and functionality of products. The process begins with selecting the appropriate plastic material, followed by heating the semi-finished product – typically a sheet – to specific temperature thresholds. Once heated, the sheet is deformed and adheres to the substrate.

This is an efficient and versatile technique suitable for a wide range of applications, from furniture component wrapping to parts used in the automotive industry.

THE MOST INNOVATIVE FINISHING SOLUTIONS

Discover the most advanced finishing solutions to boost your competitiveness.

Process steps: from glue application to cutting

More specifically, the thermoforming process can be broken down into several stages. Each is essential to ensure the final product meets quality standards.

It begins with the glue application phase, where a uniform layer of adhesive is spread onto the substrate. Ensuring maximum homogeneity in this step is fundamental, as any inconsistency may result in a weak bond between adhesive and semi-finished sheet, or visual defects in the final product. Once the adhesive is applied, the next stage involves various drying techniques that evaporate all water content, ensuring optimal adhesion.

After preparing the substrate, the heated PVC sheet is applied to the surface using a thermoforming press. The press applies both heat and pressure, enabling the film to conform exactly to the contours of the substrate. Final steps include trimming excess material to achieve clean edges and brushing to remove adhesive residue or debris.

Thermoforming process: how does it work in detail?

As previously mentioned, achieving uniformity across the panel is key; otherwise, the risk of defects after film application increases exponentially.

That’s why some recommendations must be kept in mind throughout the thermoforming process, especially during the critical initial phase: edges in particular require five to eight times more glue than flat surfaces.

Once the water in the glue has evaporated through oven drying and the PVC sheet has been applied with a press, it is essential to be precise when removing excess material.

Regardless of whether this is done manually by two operators or handled by an automatic trimming unit (which removes, collects, grinds, and disposes of sheet scraps), the rear of the panels should always be carefully inspected for any glue residue.

Variations and types of thermoforming processes

What has been described so far is a general outline: the thermoforming process is not a fixed, one-size-fits-all formula, but rather an industrial approach that includes different configurations and variants. Each has its own specific characteristics, involving the use of particular techniques to create tailored lines that meet customer demands and production requirements.

Depending on production volume and panel properties, manufacturers can choose from different types of thermoforming processes, such as vacuum forming, pressure forming, and twin-sheet forming.

Vacuum forming is the most common technique, using a vacuum to pull the heated plastic sheet onto the mould, while pressure forming employs air pressure to create more complex shapes and finer details. Twin-sheet forming, finally, makes it possible to produce hollow parts by forming and sealing two sheets together simultaneously.

Each variation offers unique benefits, so manufacturers must choose the solution that best suits their operational needs and order specifications.

The importance of adhesive application in thermoforming

Regardless of the technique used, achieving a high-quality result requires that adhesive is applied correctly – both on the surface and edges of each part – particularly when working in furniture production and wood processing.

In this scenario, one of the processes that demands the most attention and care is the application of PVC sheets to wardrobe doors, drawer fronts and panels, typically made of composite materials such as MDF.

Benefits of the thermoforming process

As outlined, thermoforming processes offer numerous benefits. One key feature making them an increasingly popular choice among manufacturers is their ability to significantly boost production efficiency: the speed at which thermoforming can be performed supports higher output rates and shorter delivery times. The process also improves finish quality, as the ability to minimise tolerances and produce detailed designs results in more visually appealing end products.

Thermoforming also reduces the need for manual labour, as many of the steps mentioned above can be automated, cutting human error and streamlining labour costs.

From an environmental perspective, the process supports companies aiming to lower their carbon footprint by reducing waste through efficient use of raw materials and facilitating the recycling of scrap materials.

In short, thermoforming not only improves production efficiency and product quality, but also aligns with modern environmental standards – making it a smart choice for the finishing industry.

Cefla and thermoforming: an integrated and customised approach

In the field of thermoforming, Cefla Finishing offers complete, integrated solutions that also cover the preliminary processing stages, such as loading the semi-finished panels and brushing/cleaning them. This is followed by all process phases previously described, including final removal of glue residue.

The real added value of Cefla’s offering lies in the customisation of production lines: depending on the customer’s needs, available space and expected production volumes, our engineers will define the best configuration to guarantee maximum productivity.

It’s not just about maximising efficiency in terms of the number of presses to feed: Cefla Finishing’s technological know-how and process expertise are placed at the customer’s disposal to develop synergistic solutions, ensuring precision and consistent application in automating a process that, if properly implemented, can free up operators for higher value-added tasks.

Thermoforming solutions

Spraying machines:

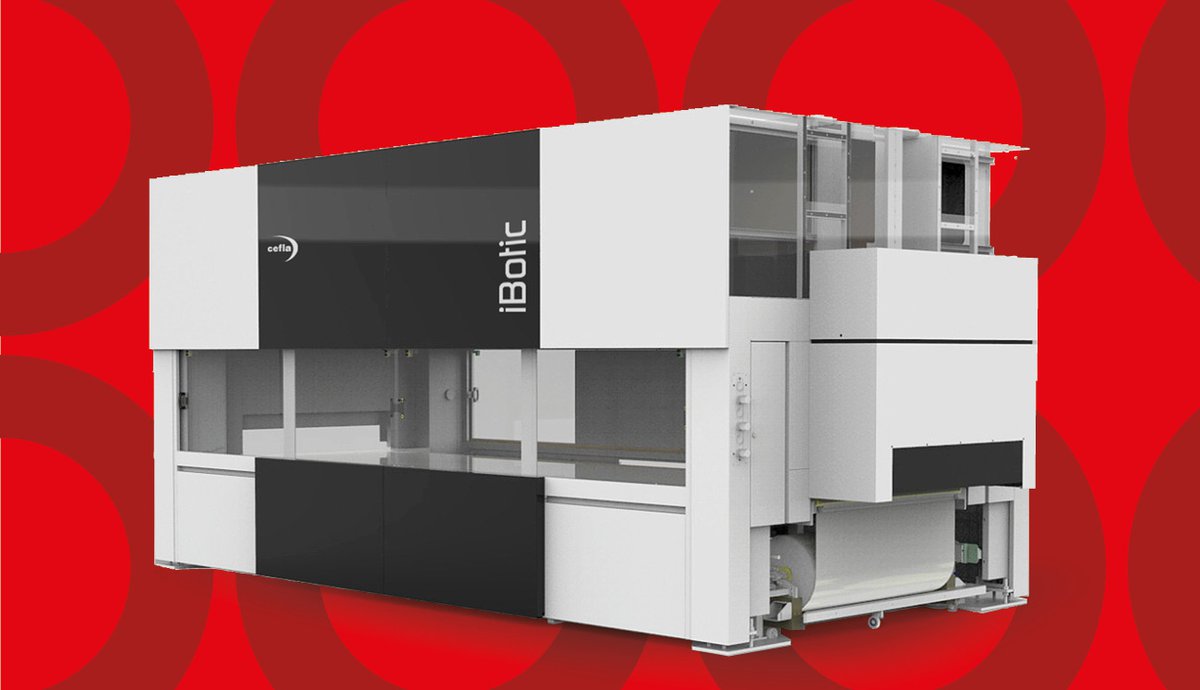

- iBotic - glue application

A high-performance five-axis application robot (configurable with one or two arms) to suit different productivity levels. iBotic solves issues related to application consistency, repeatability and operator safety. Most importantly, it ensures precise glue application, considering the difference between panel surfaces and edges. It also avoids glue contamination on the back of the panel.

- Mito - glue application only for flat surfaces

This machine ensures uniform application across the entire surface of the panel and all pieces, making it a first step toward automation for small businesses still applying glue manually. Before feeding the press (third-party equipment), we recommend maintaining a clean, dust-free environment to optimise process and application quality.

Before the press is involved (third party equipment) we recommend maintaining a clean, dust-free environment to optimise the process and application quality.

Drying Technologies

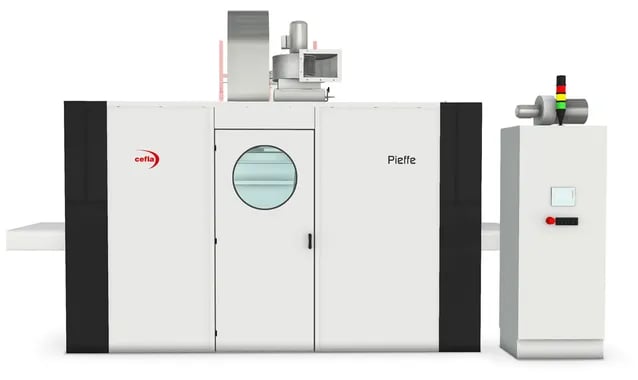

- Pieffe - hot air drying for edges and flat surfaces

A flexible hot-air oven for glue drying on flat surfaces and edges, ensuring excellent productivity.

- Aquadry - drying system for water-based glue

Water must evaporate from the glue before the PVC sheet is applied. This solution handles panels where glue has not been applied to the edges.

Trimming and scrap foil solutions

- Twister – scrap foil removal

With a compact footprint, this machine grinds and removes scrap film for recycling, helping preserve the environment while optimising the process.

- Tarcut – trimming solution

Although film trimming is often performed manually, an automatic solution provides higher efficiency and precision (guaranteed by a 3D camera that monitors each operation). Processing speed is also much higher than manual cutting.

Why thermoforming is a smart choice

By now, the value of the thermoforming process should be clear. Compared to other finishing techniques, it stands out as a versatile and efficient method for applying plastic films to substrates, offering significant advantages that improve both productivity and environmental responsibility.

As the manufacturing sector continues to evolve, mastering this process will be crucial for producers who want to stay competitive. And Cefla Finishing will always be there to provide integrated, tailored solutions

LOOKING FOR THE BEST SOLUTION FOR YOUR COATING LINE?