Article

Industrial Spray Coating: The Definitive Guide to Techniques and Equipment

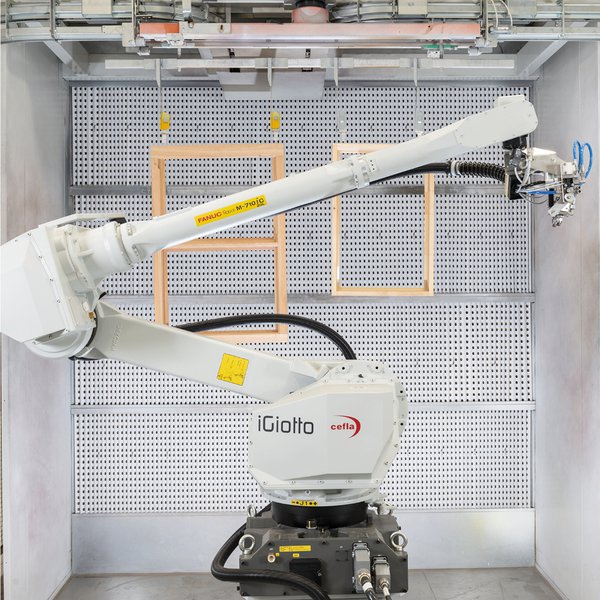

More and more manufacturers are choosing to install industrial spray coating systems within their finishing lines. Precision, flexibility, reliability and efficiency are, after all, the watchwords of a technology that, thanks to automation, can be adapted for a myriad of applications and sectors.

Naturally, to maximise output, it is fundamental to design plants and processes that take into account the unique features of the machinery and to integrate them according to production goals.

But what does it take to plan an evolutionary path that is consistent with your growth strategy? Which solutions are best to adopt to meet the needs of your specific sector?

To answer this question, we have prepared a complete guide to the techniques, equipment and use cases that revolve around the subject of industrial spray coating.

What is industrial spray coating?

Let's start by framing the topic from a technical point of view. Industrial spray coating is a manufacturing process that involves applying liquid or powder coatings to surfaces using specialised spray equipment. Unlike more traditional methods (for example, dip, brush or roller coating), industrial spray coating atomises the lacquer into fine droplets that are then transferred onto the substrates. This achieves rapid, uniform coverage on large and complex surfaces. (To learn more about this topic, we have dedicated an entire White Paper to the subject of painting complex shapes.)

Returning to industrial spray coating, the dynamics of this technology vary depending on the application for which it is implemented. In general, spray coatings provide smooth, glossy finishes for a wide range of manufactured goods, from consumer products to vehicle components, to furniture and furnishing accessories. Some coatings are formulated to perform specific functions, such as thermal insulation, electrical conductivity or non-slip properties. But there are even more particular use cases, such as the aerospace industry, as the technique, when applied with suitable materials, offers effective protection against corrosion, wear, chemical exposure and environmental factors, significantly extending the service life of products.

Industrial spray coating is increasingly valued as it supports mass production with consistent results, reduces labour costs and allows for precise control over coating thickness. Its versatility, as we will see, makes it suitable for a wide range of substrates, from metals and plastics to concrete, and for various applications.

DISCOVER THE MOST ADVANCED FINISHING SOLUTIONS

Elevate your competitive edge.

Advantages of industrial spray coating

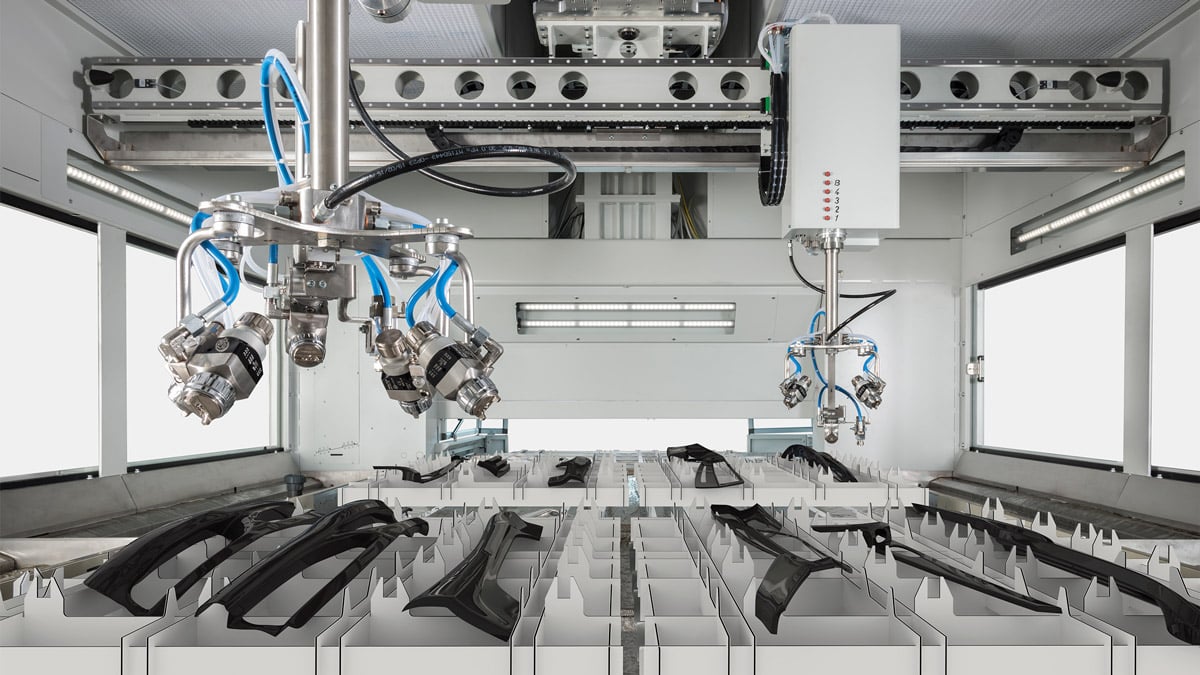

Industrial spray coating offers numerous advantages over other finishing methods. Firstly, as mentioned, its application versatility makes it possible to easily coat complex geometries, intricate components and large surfaces uniformly, a result that is difficult to achieve, for example, by brushing or dipping. This flexibility is essential for production lines that must handle objects with irregular three-dimensional shapes, such as car body panels and interior elements of motor vehicles.

But, compared to other approaches, spray coating also ensures greater performance in terms of speed and efficiency. The process can indeed be automated, which ensures high productivity and consistent results. Within a custom-designed line, spray painting can rapidly cover large surfaces, drastically reducing delivery times for large batches.

Among the plus points of industrial spray coating, one has to mention the uniformity of the applied material layer; atomisation guarantees a homogenous coating thickness, regardless of the coating material used. And, still on the subject of consumables, the wide range of materials compatible with spray coating – epoxies, polyurethanes, acrylics, zinc-rich primers and powders – allows for the creation of tailor-made solutions based on specific functional requirements:

- resistance to corrosion and abrasion from chemical agents

- durability over time, even in conditions that involve exposure to UV rays

- high-quality tactile and visual properties

- and finally, robustness

This is thanks to the ability to control the desired thickness with extreme precision, which allows manufacturers to optimise material usage and meet its performance standards.

So, in brief, the advantages offered by industrial spray coating are:

- Process speed and efficiency

- Application uniformity on complex surfaces

- Wide range of applicable materials

- Thickness control

- Resistance to wear, UV, and chemical agents

- Increased durability of treated surfaces

Common industrial spray coating techniques

Obviously, the choice and correct use of the most appropriate technique are fundamental to achieving the optimum result. Understanding the operating principle of each approach – which naturally has its advantages and disadvantages, and which is therefore more or less suitable for certain applications – is the prerequisite for maximising the performance of the coating materials on the objects to be treated.

Here is a quick reference guide to the most common painting techniques, all of which are covered by Cefla Finishing technologies and machines, with advanced and customisable solutions.

➡️Conventional Air Spray

The most basic technique uses compressed air to atomise the coating material as it exits a spray gun. In its simplicity, it guarantees excellent coverage and is extremely versatile even when using different coating types. The approach, common in general finishing operations, vehicle painting and architectural coatings, has two potential disadvantages: overspray and higher material consumption which, if not properly managed, can lead to unwanted waste.

➡️HVLP (High Volume Low Pressure)

To overcome the limits of conventional spray coating techniques, companies can turn to HVLP systems, which use a high volume of air at low pressure to produce extremely fine droplets with a controlled spray. The technique thus offers superior transfer efficiency and reduces overspray, making it ideal for precision work, furniture finishing and touch-up applications. However, you might experience a slower transfer speed for thicker coatings.

➡️Airless Spray

This approach relies on high-pressure pumps to force the coating through a nozzle without compressed air. It provides rapid coverage for large surfaces, such as industrial tanks or structural steel. The main advantage of airless spray is its high productivity; however, it can produce overspray and may not guarantee optimal finish control.

➡️Air-Assisted Spraying

This procedure, as the name suggests, combines the two aforementioned techniques (airless and conventional), using low-pressure air to further atomise the coating and improve the quality and control of the finish. Machines of this type are suitable for creating coatings that require a smooth, high-quality surface.

➡️Electrostatic Spraying

By electrically charging the coating particles, it is possible to attract them to the surfaces to be treated, ensuring greater transfer efficiency and minimal waste. Electrostatic spraying is therefore ideal for handling objects with complex shapes, such as vehicle panels and large metal structures. The resulting coating is excellent, with a drastic reduction in overspray. The main challenge in implementing this approach is the cost of the equipment and its maintenance.

Types of paints usable in industrial spray coating

The knowledgeable use of various industrial spray coating techniques allows for the adoption of a wide range of coating materials, each suitable for specific applications. Let's see which are the most common:

- Epoxy paints Known for their excellent chemical and corrosion resistance, epoxies are widely used in protective coatings for pipelines, tanks and concrete structures. They cure to form durable, high-adhesion films.

- Polyurethane paints Offering excellent abrasion resistance and UV stability, polyurethanes are common in automotive finishes, floor coatings and outdoor equipment. They provide flexible, glossy finishes.

- Acrylic paints Valued for their ease of application, quick drying and colour retention, acrylic coatings are used in architectural finishes, signage and decorative applications.

- Alkyds These are traditional oil-based coatings that offer good gloss and ease of application, often used on furniture, machinery and in general industrial applications where aesthetics is important.

- Zinc-rich primers These materials contain high levels of zinc particles for galvanic protection, preventing corrosion on steel structures, bridges and offshore platforms.

- Powder coatings (if applicable with electrostatic spraying) Applied via electrostatic spraying, powders derived from polyester, epoxy resin or thermoplastic materials produce durable and environmentally friendly finishes, particularly suitable for domestic appliances, automotive components and heavy machinery.

- Other special materials Finally, there are special coatings that offer specific properties (non-stick, heat or wear resistance) used in sectors such as the food industry, electronics or in high-temperature environments.

Industrial spray coating equipment

At the heart of an efficient, high-performance line, there is, of course, reliable and robust industrial spray coating equipment, designed to ensure quality and safety within increasingly integrated and automated processes. Here is an overview of the essential components for each of the techniques we have seen so far.

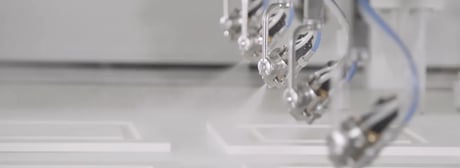

➡️Spray guns

To be selected based on the chosen technique, spray guns are divided into different categories: compressed air guns for conventional methods, HVLP guns for precision work, air-assisted guns, airless guns and finally, electrostatic guns.

➡️Material Feed Systems

We are talking about pumps (piston, diaphragm or centrifugal) and pressure pots, which supply the coating material consistently and at the desired pressure. For dispensing powder coatings, there are specialised feeders capable of ensuring a constant flow.

➡️Hoses

Essential for resisting chemical attack and pressure fluctuations, high-performance hoses connect the pumps to the spray guns.

➡️Nozzles

Depending on the type of application and material used, the guns are equipped with nozzles of different sizes and designs, which influence the spray pattern and material atomisation. Knowing how to choose the correct option is fundamental to obtaining uniform coatings.

➡️Air Preparation Equipment

Compressors, filters and dryers ensure a supply of clean, dry and regulated air, which is essential for achieving consistent spray quality and ensuring the longevity of the equipment.

➡️Surface Preparation Tools

Abrasives, detergents and primers, to be applied to substrates before spraying operations, are fundamental for ensuring optimal adhesion and coating performance.

➡️Spray Booths and Ventilation Systems

These machines not only help to reduce overspray but also to control the fumes generated by spraying, helping to keep work environments safe. Operating in tandem with adequate filtration mechanisms, they minimise the environmental impact and health risks for coating operators.

➡️Personal Protective Equipment

For those working in close contact with industrial spray coating equipment, respirators, gloves, overalls and protective goggles remain essential to avoid contact with particles that are hazardous to the skin and respiratory system.

Industrial sectors and applications of spray coating

This guide to industrial spray coating can only conclude with an overview of the most popular applications in an ever-growing number of sectors. We are talking about extremely heterogeneous sectors, each with specific requirements, but all distinguished by a common need: to achieve maximum production efficiency without ever compromising on the quality of the finished product, the safety of their employees and eco-sustainability.

While in the automotive sector these techniques have been used for years for painting car bodies and applying clear coats and protective finishes, ensuring both pleasing aesthetics and corrosion resistance, in the aerospace sector, spraying allows aircraft components to be coated with specialised, lightweight and high-performance paints.

The marine industry is also discovering its advantages: the application of antifouling paints and protective coatings helps ships and offshore structures to resist microorganisms and the constant corrosive action of salt water.

Those in the manufacturing industry, on the other hand, use spray painting to apply protective and decorative coatings to machinery, domestic appliances and consumer products, while in the construction sector, the technique is used to coat structural steel and concrete surfaces or fibre cement elements with oxidation-resistant paints and protective layers.

With the aim of obtaining high-quality finishes on wooden and metal furniture, combining durability and pleasing aesthetics, the world of furniture and domestic appliances is also experiencing the benefits of industrial spray coating first-hand.

Then there are use cases that could be defined as extreme, such as applications in the heavy machinery and Oil & Gas sectors: industrial spray coating is currently the best option for creating coatings capable of protecting pipelines, offshore platforms and storage tanks from corrosion and chemical attack. Thanks to the use of zinc-rich primers and epoxy coatings, these treatments help equipment to withstand environmental damage, wear and chemical exposure, even over a very long period of time.

Each of the aforementioned sectors can, of course, only unleash the full potential of industrial spray coating when it designs and implements customised coating solutions, that is, ones capable of adhering to industry standards and the requirements imposed by clients. This is why it is essential to be able to rely on a partner like Cefla Finishing: our offering is constantly evolving, and aims not only to provide the market with a high-level technological supply, but above all to build, together with our customers, solutions capable of successfully tackling new and increasingly challenging use cases.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR COATING LINE?