Suspended ceiling tiles: finishing technologies

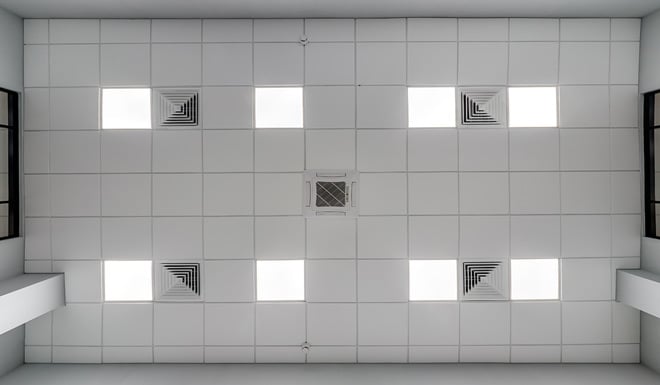

In the construction industry, suspended ceiling tiles - known also as drop ceilings - are a common feature for residential or commercial buildings. They are made up of a grid framework and a series of tiles made of rock wool or similar composite material.

Types of ceiling tiles

Suspended ceiling tiles can be simple in shape, square or rectangular, with regular edges and a consistent thickness across the extent of the panel. These are commonly referred to as lay-in tiles and fit into the grid, flush with the supporting structure.

The second most common tile, often called a tegular tile, has what is called a revealed edge, so that when placed on the supporting grid, the panel protrudes downwards creating a pattern made up of several tiles with gaps between one tile and the adjacent tile.

Surface and edge finishing according to tile type

Coating of the visible flat tile surface is done on any spray coating machine, whereas the edge is processed using vacuum coating. Our integrated solution enables manufacturers of the ceiling tiles to process the edges in a fast cycle.

When dealing with tegular type profiles, our technological solutions – such as Talent, the patented vacuum system for the sealing of edges - enable you to apply different paint grammage with the same vacuum application head to different sections of the edge. This means you can use more coating on the exposed edge and less coating on the unexposed edge, saving money on the sealing substance where it is less necessary.

Furthermore, there is no risk of overspray on the panel surface, drying using infrared lamps is a rapid step in this single-pass process, and colour changes, if needed, are fast.

If you are interested in examining our solutions for drop ceilings, please contact us for more details.