Today, flatbed coating lines can play a fundamental role for companies in the automotive sector. The thought goes primarily to those players who, in an aim to strengthen their positioning in the sustainable mobility market, focus on manufacturing vehicles mainly made from lightweight and easily recyclable materials. To be precise, we are talking about plastic, particularly for the production of interiors that must be functional, resistant and aesthetically satisfying.

Finishing and decoration processes for plastic components therefore become an integral part of a value chain that aims to combine perceived quality, performance and low environmental impact. And this is exactly where flatbed solutions come into play.

What flatbed coating lines are

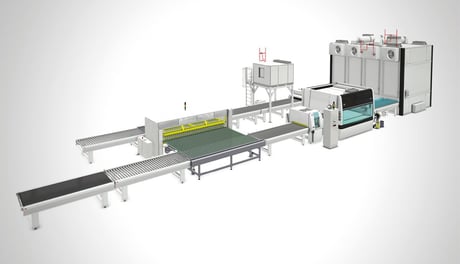

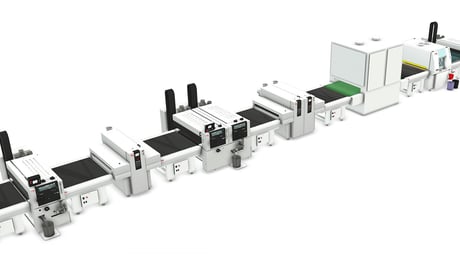

Let us start by defining this approach to finishing. A flatbed line, as the name suggests, is based on an architecture that features a flat and stable surface for material processing.

Generally, the solution consists of one or more in-line conveyors where the products are placed to undergo various operations required for their coating. Positioning the parts flat—usually fixed onto support frames—allows uniform treatment across all parts, with higher productivity compared to traditional solutions.

This principle has made flatbed lines essential tools in finishing processes that aim to optimise material handling and coating operations. This facilitates quality control, improves overall production efficiency and reduces waste.

THE MOST INNOVATIVE FINISHING SOLUTIONS

Discover new finishing solutions: more effective, more productive and more competitive than those currently used by the industry.

The benefits of flatbed coating lines in the automotive sector

This is why, in the automotive sector, adopting a flatbed line can offer several advantages over more traditional coating solutions. The main benefits are:

Efficiency and speed.

Flatbed lines are designed for continuous operation, enabling faster processing times. Thanks to their greater width, they can handle more pieces simultaneously, significantly reducing production times compared to traditional methods.

Repeatability and quality.

Automatic flat coating systems guarantee uniform coverage and consistent quality on all parts. This reduces the variability typical of manual coating, leading to superior finishes and fewer defects.

Optimisation of process stages.

Cefla flatbed lines have independent conveyors, allowing different advancement speeds in the various stages of the process. This means that loading, cleaning, coating, flash-off, drying, unloading and quality control times can be adjusted according to the specific requirements of each stage, independently of one another.

Cost control.

Although the initial investment in a flatbed line may be higher, long-term savings are substantial. Reduced labour costs, lower material waste, reduced energy consumption and increased productivity generate an extremely rapid ROI.

Versatility.

Flatbed lines can process a wide range of substrates, sizes and shapes. This flexibility enables manufacturers to work with different types of products without having to modify coating programmes, making it easier to respond to changing market demands.

Improved environmental control.

Modern flatbed systems include features that control overspray and manage VOC emissions more effectively than traditional methods thanks to lower and optimised airflow rates.

Monitoring and data collection functions.

Advanced flatbed systems can be equipped with integrated monitoring and data collection capabilities, allowing manufacturers to assess performance, optimise processes and take data-driven decisions for continuous improvement, as well as enabling traceability by matching process data with the parts produced.

Flatbed lines vs. traditional coating systems

But when is it really advisable to use these solutions?

If vertical spray coating lines are more suitable for handling larger components (such as bumpers), smaller parts—such as those used in car interiors, generally made of plastic—have different requirements.

Flatbed lines, besides ensuring better productivity, deliver better quality because overspray—typically responsible for defects in this type of processing—is removed from below.

In particular, the Cefla Finishing flatbed finishing solution not only offers 20% higher productivity compared to traditional systems but also delivers excellent glossy black (piano black) finishes on plastic components.

Cefla’s approach: integrated lines for a fully automated coating process

There is another element to consider. Today, the needs of entrepreneurs and plant managers receiving orders from the automotive world increasingly move towards complete solutions, including:

- equipment for automatic part cleaning, increasingly using dry ice with no environmental impact

- spraying robots with reduced—or zero—programming requirements

- large ovens and UV lamp systems for in-line drying

The flatbed approach fits perfectly with this philosophy.

At Cefla Finishing, we specialise in designing flexible, complete and turnkey finishing solutions. A Cefla flatbed coating line for piano black interior parts includes the following stages:

- Surface preparation:

Automatic cleaning with dry ice and deionisation with the Mito oscillating spray coater. - First coating application:

The components pass through a 2D or 3D reading barrier into the iBotic cartesian spraying robot for the application of the basecoat. - First drying:

the coated components move into the Omnidry vertical oven for 20-30 minutes. - Second coating application:

A new clearcoat layer is applied, again by the iBotic cartesian spraying robot. - Final drying:

Passage through the Omnidry oven for 45 minutes at 70°C, and optional double curing using ultraviolet lamps in the UV oven (UV-R M2)to increase surface hardness.

Automation in coating lines: from robots to monitoring software

There are also components that require different processes. How can these be managed automatically and intelligently within a flatbed line? The answer comes from Cartesian robots and, above all, from line software such as cTracker.

This tool monitors the line and automatically regulates coating operations and process parameters, such as the correct temperatures for subsequent drying. In this way, each component can receive the most suitable treatment without slowing down or stopping production.

But this is not the only advantage. Thanks to cTracker, it is also possible to monitor the pieces on the line, record data and analyse productivity. These features allow production changes to be implemented without emptying the line, managing and tracing each part frame from a single point and adjusting all machines according to preset recipes or real-time needs.

In conclusion

In the automotive sector, the needs for innovation and sustainability find a response in flatbed coating lines, which stand out for quality and efficiency in producing plastic components for car interiors.

Adopting integrated flatbed lines is, in short, a strategic choice for companies aiming to position themselves at the forefront of the market, combining superior production performance with impeccable quality results.

Want to switch to a flexible, efficient and premium-quality coating system? Contact us—our experts are at your disposal for a professional consultation.