Flat surface roller coating technologies have evolved since introducing our first roller coater nearly 60 years ago. In 2000 we launched the Smartcoater, and since then we have regularly renewed the range in line with the market’s requirements.

Today our customers are asking us for more flexibility, a greater degree of automation and savings, both in terms of time and costs. These are the key issues to which we have added further benefits when developing the latest addition to the range: Smartcoater PRO.

How flexible can we get?

Built to process all types of material (only flat surfaces) - wood and its derivatives, as well as glass, cork, metal, fibre cement and plastic - Smartcoater PRO gives customers the chance to gain greater control over their process, over the lacquer applied and over productivity in general. Handling all sorts of products, they require flexibility and better performance: one machine for all product types. Different shapes, different thicknesses, uncalibrated panels all require flexibility. But variations in lacquer also influence the operating parameters and based on temperature, viscosity and other variables, machine settings need to be adjusted. Instead of doing this manually, we have designed a platform which automates parameter regulations, saving time and improving performance.

How can we lower production costs?

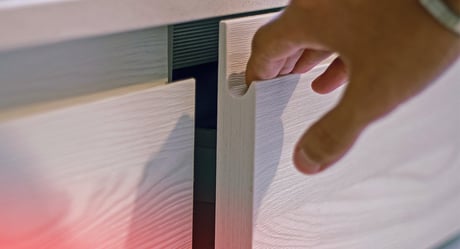

Customers also want to save on lacquer, solvents, cleaning operations, and they are looking for a solution any operator will feel at ease monitoring all these parameters. We have built Smartcoater PRO so that operators can see inside the machine to check key parts are working correctly. Cleaning operations are partly automated and use of a roller cleaning device reduces solvent consumption and costs substantially. Automation also plays a role in reducing production costs by monitoring coating parameters (weight of lacquer, temperature, etc.) and thereby adjusting dose roller pressure automatically. Recalling a specific recipe will adjust parameters accordingly without added manual intervention.

What else is new compared to previous roller coaters?

An improved lifting system based of 4 screw jacks ensures greater stability and sturdiness. Furthermore a floating system with optional pneumatic control responds perfectly to surface variations on flat panels transiting through the machine. Belt adjustments are now automatic, with an optional belt-centring system. Belt change is quicker than on the previous version. Smartcoater PRO also features dose roller positioning and an independent electric application device.