Efficiency, sustainability and productivity in a double-sided profile wrapping solution

Project Details

Customer:

Profine Group

Country:

Germany

Media Video:

Who’s the customer?

Berlin-based Profine Group, whose annual production volumes reach around half a million tons of PVC processed in 29 permanent sites spread across 23 different countries worldwide, manufactures and commercialises under the brands KBE, Kömmerling and TROCAL, PVC profiles for windows and residential doors, shutter systems and PVC sheets.

The challenge

Although the company already had 2 Duespohl machines and were extremely satisfied with their performance, the 2 new profile wrapping machines needed to fit into the extrusion lines and there would be much less room. It was a challenge to fit all the electrical equipment into such a small footprint, but the machines were designed carefully to provide the answer. The company also wanted us to find a solution that would improve overall sustainability in all ways possible.

The Düspohl solution

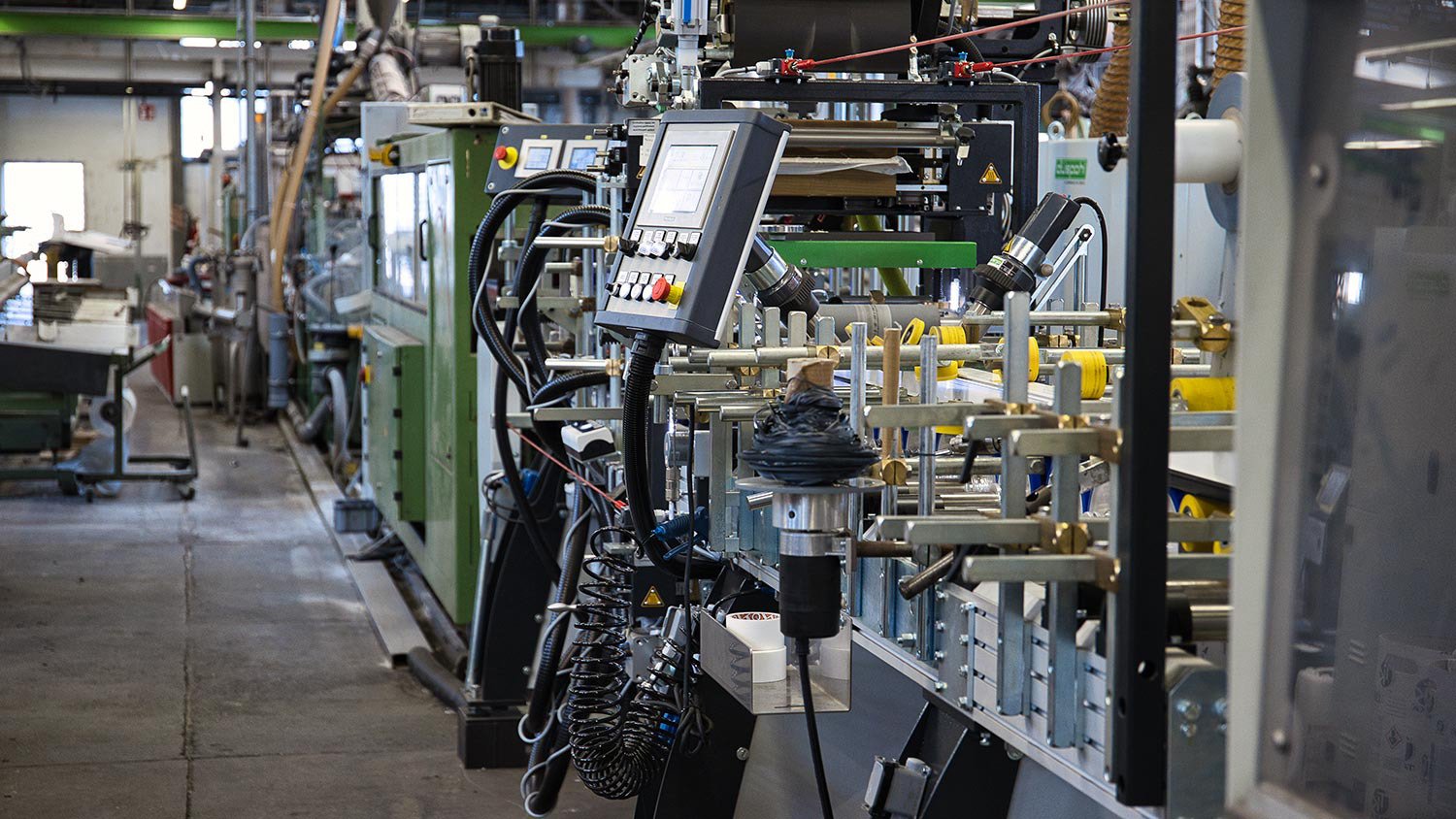

Tailoring the design to fit the smaller factory space and integrating our equipment with the extrusion lines, we delivered a solution that could wrap both sides simultaneously or individually upper and lower sides of the PVC profile. We also supplied PrimeStar, our unrivalled primer application technology for VOC reduced systems.

Results

Just as the original Düspohl machines from 2014/2015 proved to have been one of the best and most efficient investments made, the 2 new inline profile wrapping machines increased productivity, avoided extensive material handling between extrusion and wrapping and led to reduced energy consumption as the heat from the extrusion process facilitated the wrapping process which came directly after extrusion.

Increasing output came together with increased sustainability

Based on the first positive investment experience, profine decided to integrate two more wrapping lines into the extrusion lines. The resulting simultaneous wrapping of the upper and lower side increases productivity, lowers the need for human intervention and replaces entire machines.

"Based on our initial experience with Duespohl technology, it was a no-brainer to choose to invest in two more machines, allowing us to ensure the capacity for coming years with these highly efficient lines. The inline profile wrapping process not only increases our productivity, it is also an essential element of the Group’s sustainability strategy."

Christian Amling - Chief Operating Officer (COO) at profine Group

Project Gallery