Focus On

ENVIRONMENTAL COMPLIANCE

100% solid UV coatings are solvent-free and cure through polymerization rather than evaporation. The system is designed to minimize VOC emissions.

Description

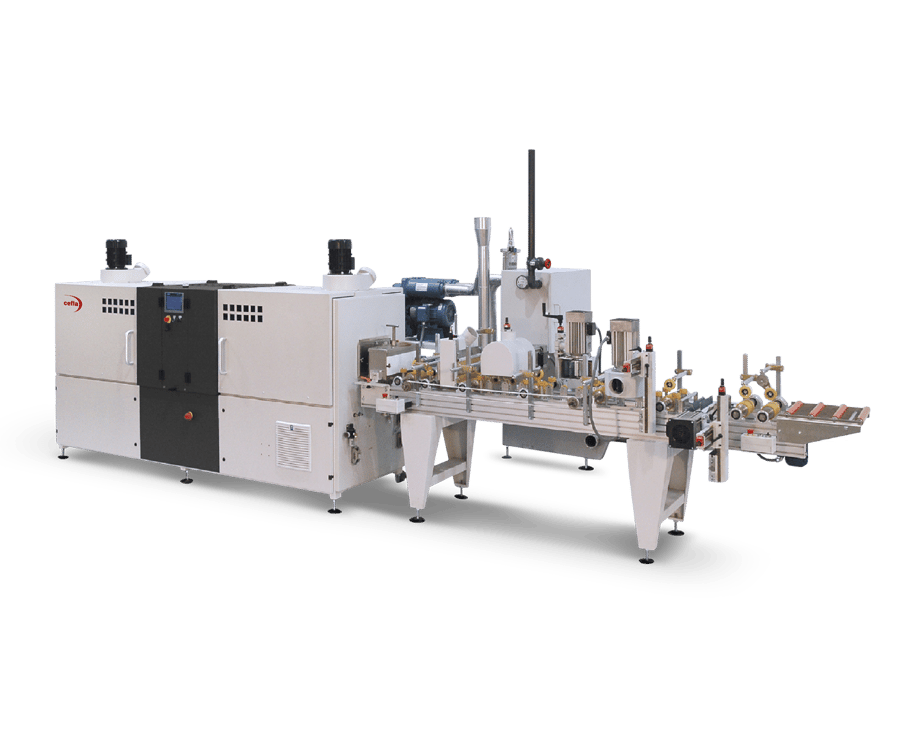

The CVS UV Finishing System can meet the needs of any coating formulation to match color, sheen, abrasion, and chemical resistance. In addition, the process provides total control of the cure temperature, making it ideal for heat sensitive substrates and/or applications.

Achieve today's most sought-after and cost-effective finishes in a compact, fully-featured production machine.

The CVS is the only moulding finishing system for UV that incorporates Sanding, Coating and Curing in a single system.

Sanding:

A motorized roller conveyor with center adjustable guides and hold-downs provides the infeeding platform on which the sanding wheel units can be fitted and individually positioned to sand up to all 4 sides of the profile.

UV Coating:

Coating is pumped into the application head which is outfitted with a front and back tamplet gate. The substrate is pushed through the gates where it is coated on selected sections or on all 4 sides in a single pass. The negative pressure inside the chamber pulls the surrounding air, at a controlled speed, through the small fissure around the substrate and draws the excess coating back into the separation tower. Coating is continuously recycled, making the CVS UV Finishing System an economical and environmentally-conscious solution.

Curing:

Freshly coated substrate is fed into the curing tunnel for instant all-around polymerization of the photosensitive coatings by multiple UV-lamps. Sliding doors allow easy access to the UV lamps for easy adjustment and maintenance forced and filtered air maintains adequate cooling of lamps and radiation chamber

Designed with small- to medium-sized productions in mind, the CVS series is simple to install, use and maintain.

Characteristics

- Ideal for small- to medium-sized production requirements

- Simple to install, use and maintain

- Easy-to-use touch-screen control

- Sanding: Individually positioned sanding wheels on all four sides for single-pass production

- High powered UV with electronic intensity adjustments

- Low VOC’s

- Fast profile changes

- Low coating costs

- Small foot print

- 360º coating capability

- Closed loop system offers maximum transfer efficiency and minimized coating waste