Article

Machines for profile wrapping: applications, technologies, and advantages

Profile wrapping machines are becoming essential tools for manufacturers aiming to achieve a dual result: improving the aesthetics and increasing the durability of their products. The technologies and applications revolving around this technique, after all, continue to increase, generating tangible benefits especially for the furniture sector and, more generally, for woodworking.

What is a wrapping machine?

A profile wrapping machine is specialised equipment designed to apply decorative and protective materials to profiles usually made of wood, MDF and composite materials.

More specifically, we are talking about automatic machines that use various types of adhesives and a wide range of thin materials (such as vinyl, paper and laminate) to wrap edges and corners. This produces a surface finish that enhances the visual appearance and also extends the product's life cycle by protecting it from potential chemical and physical damage. The profile wrapping technique can be applied to a multitude of components and semi-finished products including mouldings, cabinet doors, furniture frames and other everyday items.

How profile wrapping technology works

The technology behind profile wrapping is based on principles of precision mechanical engineering. It could not be otherwise, given that a uniform application of all materials involved in the process is needed to ensure an optimal result.

Each profile wrapping machine usually works by feeding a profile through a series of rollers and adhesive application units. The process begins with surface preparation and cleaning, followed by the application of the adhesive that best meets the needs of the specific use case.

The wrapping material is then fed over the profile, where it is carefully wrapped and pressed into place, ensuring perfect adhesion. This mechanism, once automated, allows for high-speed processing and consistent quality, which makes it ideal for high-volume production environments.

Wood profile wrapping process

Naturally, the operation is part of a more complex supply chain. The wood profile wrapping process begins with the selection of the appropriate material and adhesive, which can vary based on the desired finish and the end use of the product.

Once prepared, the profile is fed into the machine, where the adhesive is applied uniformly. Finally, the wrapped profile undergoes a quality control check to ensure it meets industry standards before being packaged for shipment.

What has just been described can be considered a standard process. If carried out with the right parameters, it is extremely efficient and minimises waste, maximising productivity.

Advanced profile wrapping technologies

With a view to meeting increasingly specific needs, recent years have seen a continuous refinement of profile wrapping technologies. Profile wrapping machines have significantly increased their capabilities, incorporating advanced functions.

These start with automatic material feeding, which are increasingly being supplemented by real-time process monitoring systems and integrated cutting solutions. These innovations, acting in synergy, not only simplify complex wrapping operations but also improve the precision of the output. Furthermore, there is a drastic reduction in downtime with a lower number of products failing quality control.

The new generation of machines is capable of wrapping complex shapes and profiles, which allows manufacturers to diversify their offerings and satisfy even the most demanding customers.

DISCOVER THE MOST ADVANCED FINISHING SOLUTIONS

Elevate your competitive edge.

Decorative wrapping solutions for profiles

But, when it comes to innovation in profile wrapping machines, another element is of greater interest. The latest solutions are able to integrate highly versatile decorative techniques, which expand the range of results achievable with this technology.

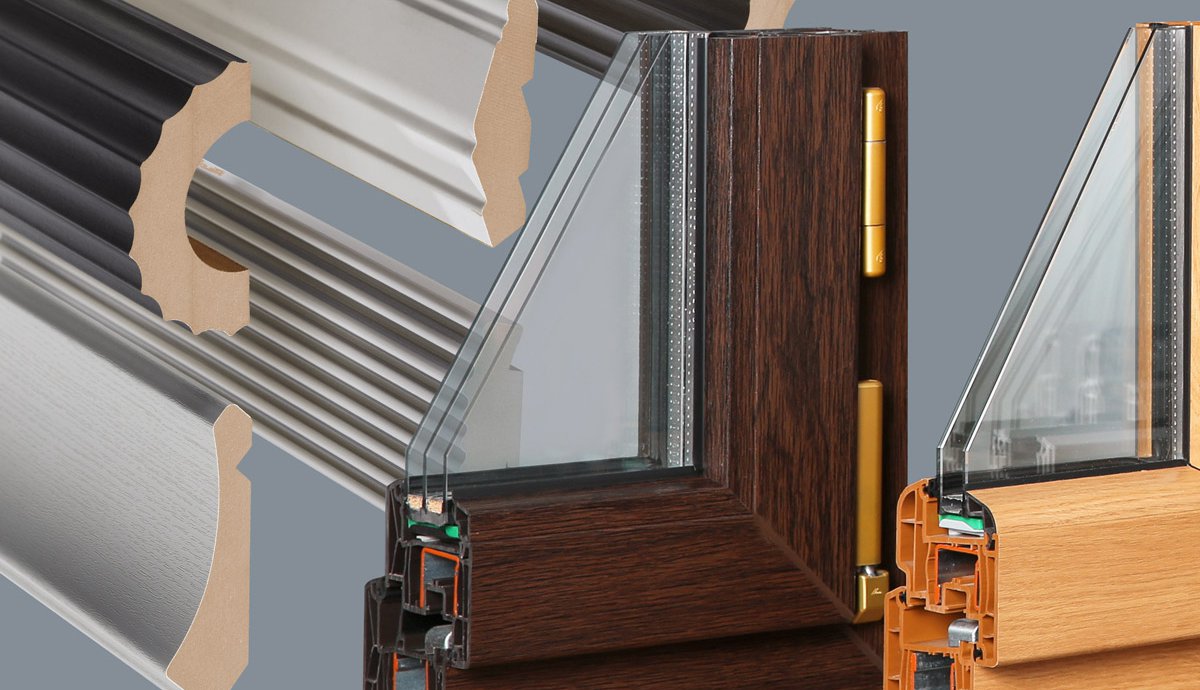

Indeed, operators today have the real possibility of choosing from a wide range of materials, colours and textures (including wood grains and other natural patterns, bright colours and even metallic finishes) and applying them to various types of profiles without substantially altering the production process.

The aesthetic improvement guaranteed by the wrappings is not limited to giving profiles greater appeal. It increases their perceived value, transforming the tactile and visual properties of the wrapping material into marketing tools. Therefore, manufacturers today have an extra ace up their sleeve to entice their customers.

Profile wrapping for furniture components

It is therefore no coincidence that profile wrapping machines are finding so much space in the woodworking and furniture industry. A quality wrapping makes it possible to seamlessly integrate components made of different materials, while a uniform finish helps to achieve a cohesive look among the various pieces that make up an item of furniture. Nor should one underestimate the fact that more sophisticated and elegant designs are accompanied by new qualities of durability and resistance.

These are fundamental factors that determine the quality of particularly exposed components, such as cabinet doors, drawer fronts and table edges. Thanks to the application—via new wrapping techniques—of highly effective protective layers, finished products can now be protected from scratches, moisture, UV damage and other environmental factors like never before.

Industrial profile wrapping: advanced functions

A wrapping machine is designed to meet the needs of large-scale production facilities. Speed, efficiency and reliability are, after all, the watchwords for companies that are always trying to respect the delicate balance between high volumes and high quality. But as those in the industry know well, ensuring speed, efficiency and reliability means, first and foremost, reducing machine downtime to a minimum.

Advanced features and software with advanced controls are a response to this challenge. But that's still not enough. Many wrapping or covering processes require the use of specific glues, which entails an increase in costs and energy consumption. The goal is therefore to decrease this need through technologies that allow the right amount of adhesive to be weighted for each application.

The integration of Industry 4.0 principles moves in this very direction, making it possible to constantly optimise even this type of process as new operations are implemented. This results in a significant reduction in energy and material consumption.

Wrapping solutions and machines designed by Cefla Finishing

Among the most advanced wrapping machines on the market, capable of catalysing all the prerogatives just described into a single line, are the solutions from Cefla Finishing and Düspohl (Cefla's brand specialising in wrapping solutions). Through these two offerings, we provide our customers with the best of technologies and know-how for wrapping wood, plastic and aluminium profiles.

First and foremost, our wrapping machines are equipped with the patented Click-Fix system, which enables wrapping rollers to be changed without the use of other equipment. The transport rollers are also adapted to the process, fixing themselves automatically, thanks to a grid system.

The melters on Düspohl and Cefla machines enable a continuous refilling process without needing to stop production, also minimising glue waste, which is applied to each wrapping in the exact quantities needed to ensure the optimal result. Not a drop more, not a drop less.

Moving up the range, the RoboWrap solution is equipped with a computerised system for the automatic measurement of the geometry and diameter of each individual pressure roller after the wrapping process. RoboWrap is thus able to consider the wear of the pressure rollers and manage the process dynamically, to ensure reliable results even during long production cycles. All components of each of the machines designed and manufactured by Cefla Finishing or Düspohl are also continuously updated and optimised.

The goal is to reduce profile changeover times without ever compromising on quality, which must remain a constant. This is an approach that in Düspohl solutions is also expressed through customised configurations, capable of meeting the needs of specific customer projects. In other words, the basic equipment is integrated on a case-by-case basis with components that can increase the productivity and safety of the process in the use cases for which the machine was developed.

Cefla Finishing's commitment to sustainable wrapping machines.

The focus on maximum efficiency and the correct use of materials is just one of the aspects of the commitment that Cefla Finishing puts into implementing a sustainable business strategy. Also on the profile wrapping machines front, Cefla continues to invest in solutions capable of combining high performance and low consumption with ever-increasing effectiveness.

By integrating frontier technologies, such as the Internet of Things, Big Data Analytics and Artificial Intelligence, Cefla Finishing's designers are already creating a new generation of machines, which through extensive customisation of functionalities will be able to further reduce the impact of wrapping operations.

LOOKING FOR THE IDEAL SOLUTION

FOR YOUR FINISHING LINE?