Article

Industrial Roller Coating: A Guide to the Most Innovative Technology

In recent years, industrial innovation has revolutionised the concept of surface finishing. Industrial roller coating has established itself as an efficient and versatile technology for companies focused on quality and productivity. This guide explores the advantages, processes, customised solutions, and the latest applications made possible by Cefla Finishing technologies.

What is industrial Roller Coating

Industrial roller coating is an application technology that employs sets of specialised rollers to apply lacquers or other coatings onto different types of substrates. More than a simple technology, it is a method widely used in production processes to ensure uniform, efficient, and high-quality finishes.

The role played by rollers in industrial coating

As the name suggests, the main component of a roller coating machine is the roller itself, a cylindrical tool designed to rotate and transfer the coating material onto surfaces. Rollers can be covered with different materials such as rubber, polyurethane, sponge, or silicone, each chosen according to the specific requirements of the application. Soft rubber rollers, for example, offer excellent elasticity and adhesion, making them suitable for treating irregular surfaces. Polyurethane rollers, on the other hand, provide durability and chemical resistance, particularly when more aggressive lacquers are used.

The operation of industrial roller coating solutions involves a combination of movements aimed at applying the lacquer and pressing it onto the material to be treated. This synergy produces a smooth and uniform finishing layer, though the result may vary depending on several factors. The type of roller coating material and its surface structure significantly influence the final appearance of the workpiece, which may feature glossy, matt, or textured finishes depending on the chosen solution.

Let us now look more closely at the advantages these techniques offer, and how Cefla Finishing’s innovative solutions — starting from soft rollers — help leading players across various industries position themselves on the market with products of impeccable quality.

The main advantages of correctly implementing industrial roller coating

Industrial roller coating is a technique with deep roots in traditional finishing approaches. Significant technological advances in recent years have revolutionised its role, expanding its uses and significantly increasing the efficiency of the machines.

Firstly, new-generation solutions allow uniform application not only on flat objects, but also on complex or irregular surfaces, reducing material waste and ensuring consistent finish quality by eliminating defects typical of traditional techniques, such as streaks or uneven coating layers, which are costly and time-consuming to correct.

Machines in the past were often unable to apply sufficient pressure to panels during coating. Operators were unable to control the process satisfactorily, and the poor quality of the result was only noticeable at the end. In addition, the application heads did not work on poorly calibrated panels or uneven surfaces. Manual cleaning of the machines was also time-consuming and costly.

Today's solutions overcome these limitations, improving operational performance and increasing application speed without sacrificing quality. Faster processing times translate into higher productivity and reduced labour costs.

Last but not least is the issue of sustainability: the new machines reduce VOC emissions and optimise resources, resulting in lower lacquer usage and energy consumption.

THE MOST INNOVATIVE FINISHING SOLUTIONS

Discover the most advanced finishing solutions to boost competetiveness.

The typical industrial roller coating process: the main stages

The industrial roller coating process involves several stages, each of which is essential for achieving optimal results. A typical line involves six steps:

- Initial analysis and machine configuration: understand the material, surface geometry and coating requirements to set the process parameters.

- Surface preparation: this may include sanding, cleaning or applying primer for better adhesion and uniformity.

- Coating application using rollers: the product is transferred to the substrate using precisely adjusted and calibrated rollers.

- Drying: UV ovens, infrared heaters, or drying chambers cure the paint.

- Inspection and quality control: visual and instrumental checks ensure the desired thickness and adhesion.

- Delivery: coated components are packaged and prepared for shipment or assembly.

Each stage is crucial: incorrect preparation can compromise adhesion, while inadequate polymerisation can lead to premature wear. A well-orchestrated process ensures a durable finish, optimising production and reducing waste.

How to choose the industrial roller coating solution that best suits your needs

Moving from theory to practice means evaluating various parameters and understanding what upgrades to make to your systems. Choosing the ideal industrial roller coating solution requires a comprehensive analysis of multiple factors.

Knowledge of the operating environment is essential. Applications exposed to high temperatures, humidity or chemicals require specific properties in the coating and rollers. The material to be treated (metal, plastic, wood, composites) determines the choice of roller and coatings. Mechanical loads, operating speed and type of finish influence the selection process.

Budget, machine life, maintenance costs and energy requirements also play a role in the choice: modular solutions help to evolve according to needs.

Other technical criteria: system efficiency, low material consumption, compliance with environmental regulations (e.g. low VOC).

Efficiency, ease of use, accessibility and control of the machine process are also fundamental. The user interface must be intuitive even for inexperienced operators, and maintenance/cleaning operations must be quick.

Finally, real-time or remote monitoring should not be overlooked: constant control, intuitive interfaces and easily controllable functions are required.

Cefla Finishing takes care of every aspect of the design of its solutions, helping each customer to maximise efficiency and optimise resources based on real business needs.

Why customised industrial roller coating solutions make the difference

Standard offerings are not always sufficient for complex industrial applications. Customised roller coating solutions allow you to meet specific operational requirements. A customised approach adapts the line to particular materials, surface geometries and environments.

By developing tailor-made solutions, companies gain better control over the application and reduce waste. A customised roller coating system can optimise thickness on delicate (up to 0.3 mm) or intricate surfaces.

Investing in these solutions also means equipping yourself with future-proof technologies: modular systems can be upgraded as production grows through targeted revamping, ensuring sustainability and operational flexibility even in the medium to long term.

Customised solutions are a strategic choice for those seeking operational excellence, cost rationalisation and technological innovation. Cefla Finishing acts as a consultant and partner, not just a technology supplier.

Smartcoater PRO: the soft application roller and other innovations that make the difference

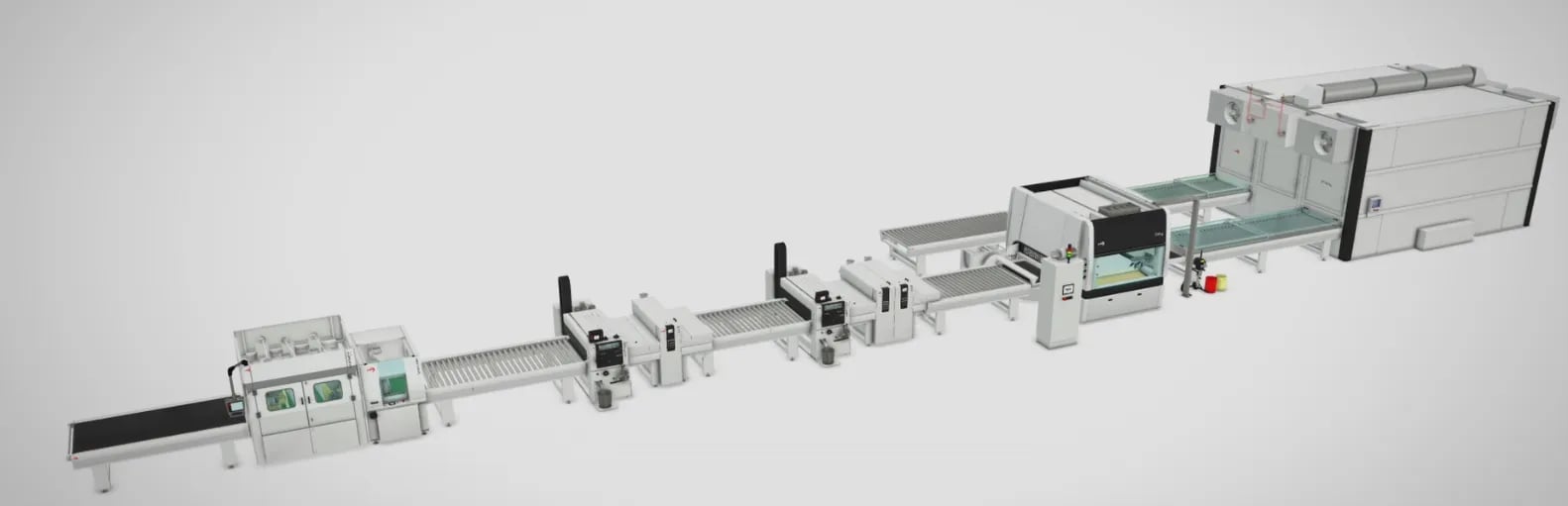

Cefla Finishing's expertise and capacity for innovation are embodied in Smartcoater PRO, the industrial roller coating machine designed to meet the needs of modern finishing lines.

Equipped with four screw jacks for a rigid structure, Smartcoater PRO is able to exert greater constant pressure on the panels. The integrable pneumatic floating system allows lateral movement of the application head, compensating for irregularities or poor panel calibration.

The result is uniform coating and a drastic reduction in waste. Thanks to its soft rubber application roller, Smartcoater PRO can also perform operations such as base coat coating on raised panels with shallow grooves, minimising paint consumption compared to traditional spray application while maintaining precision and speed.

With Smartcoater PRO, hybrid lines can be installed: two roller coating stations and a spray coater for the finishing layer. This offers benefits such as:

- greater transfer efficiency and reduced paint consumption;

- reduced solvent consumption and lower emissions;

- fewer steps in the line, with less risk of product damage;

- improved production speed and shorter delivery times.

Industrial sectors that benefit from specialised roller coating

Advanced technologies such as Smartcoater PRO are extremely versatile and applicable in many sectors:

In the wood industry, precise coating ensures aesthetics and durability for furniture and accessories. In the steel industry, roller coating allows for protective and decorative applications against corrosion and wear. In printing, paper and packaging, uniform applications guarantee print quality and product protection.

In textiles, roller coating adds water resistance and special textures. The automotive and aerospace sectors are also increasingly using this technology to meet safety and performance standards.

Cefla Finishing offers tailor-made solutions for all these markets, providing its expertise for innovation and customisation at the highest levels.

ARE YOU LOOKING FOR THE IDEAL SOLUTION FOR YOUR ROLLER COATING LINE?

Use our expertise to solve your needs

Use our expertise to solve your needs