Article

Guide to plastic processing and coating

Plastic processing plays a crucial role in several industrial sectors: polymers make it possible to manufacture parts that are versatile, cost-effective, ergonomic and easy to assemble.

The main techniques used in plastic processing include injection moulding, extrusion, compression and thermoforming, each designed to produce specific shapes and functionalities. Increasingly common is the manufacture of carbon parts obtained by layering sheets inside a mould, followed by an autoclave forming process to achieve the desired component.

Increasingly so, coating is being added to these processes, through which paints or surface treatments are applied to enhance the appearance and performance of plastic items, making them more attractive or resistant to use.

Surface layers and protective coatings increase resistance to environmental factors and the overall longevity of the workpiece, making plastic suitable for an infinite range of uses.

Industrial applications of plastics

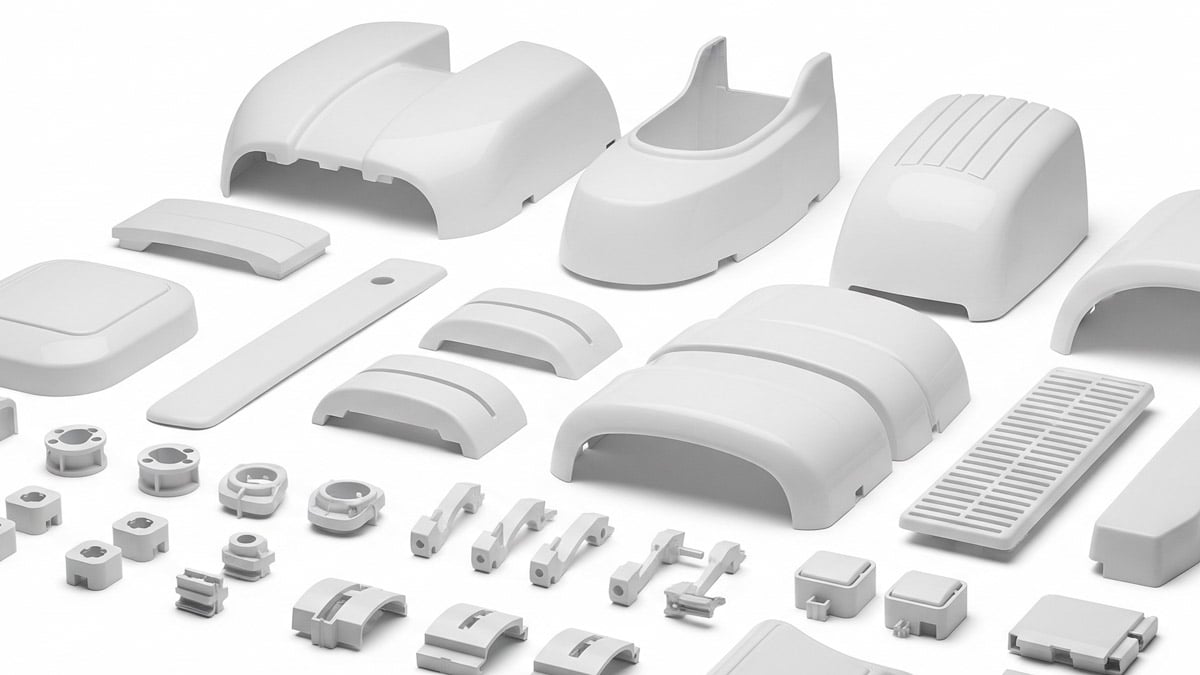

The industrial applications of plastics are countless. Often chosen for their unique properties, plastics are used in strategic sectors such as automotive, aerospace and electronics.

Safety and cost reduction: plastics in the automotive industry

In automotive applications, for interior and exterior coatings, injection-moulded plastics allow complex shapes to be created, integrating aesthetics with functionality while keeping operating costs relatively low. Plastics such as polypropylene, polycarbonate, ABS, polyurethanes and their combinations are used to produce components such as bumpers, dashboards and other vehicle parts.

The reasons are twofold: plastic materials not only enable aesthetically appealing parts to be produced, but they also reduce vehicle weight, improve fuel efficiency and reduce emissions, contributing to environmental sustainability and compliance with regulatory standards.

Fuel tanks are often made of high-density polyethylene, which ensures corrosion resistance while being lighter than traditional metal tanks. This choice improves vehicle safety, since plastic tanks are less prone to puncture and can be moulded into more complex shapes to fit specific designs.

Plastics and aerospace: a partnership driven by innovation

The aerospace sector uses advanced composites, such as carbon fibre reinforced polymers, in structural components such as wings, fuselage sections and tail assemblies. These materials offer lightness and strength, improving fuel efficiency and aircraft performance.

Inside cabins, plastics and composite materials are used to manufacture seat parts, overhead bins and side panels: this choice also contributes to reducing overall aircraft weight.

The electronics industry, in pursuit of durability and resistance

In electronics, ABS and polycarbonate are commonly used to produce casings for smartphones, laptops and other small consumer devices. These materials offer durability, impact resistance and ease of production, also enabling elegant and distinctive designs.

Even circuit boards benefit from plastic processing: in particular, laminated plastics are used as substrates for printed circuit boards thanks to their excellent dielectric properties, which favour the miniaturisation of electronic devices.

Main techniques of plastic processing

In each of the sectors mentioned above, plastic processing is carried out using different techniques. Among the most widespread methods, as mentioned, are injection moulding, extrusion and thermoforming, each offering specific advantages depending on the desired output.

Injection moulding

Injection moulding is a widely used technique involving the pressurised injection of molten plastic into a mould cavity. This process allows for high precision and large-scale production of complex shapes; it is ideal for manufacturing intricate design items such as car parts and household objects.

Extrusion

Extrusion, on the other hand, involves forcing molten plastic through a shaped die capable of creating continuous profiles such as tubes, sheets and profiles.

Thermoforming

Thermoforming is a technique that uses heat to soften plastic sheets, allowing them to be moulded into specific shapes using dies. Thermoforming is a more economical process than the previous ones, given the lower cost of the dies, and is therefore suitable for producing small batches or large parts.

DISCOVER THE MOST ADVANCED FINISHING SOLUTIONS

Elevate your competitive edge.

Coating: the most important phase in plastic processing

Once the parts are produced, the coating phase follows. This is a crucial process in plastic processing, as it significantly enhances the aesthetic and functional qualities of the final product, adding value even to low-cost items and increasing their perceived worth.

Coating and surface treatment techniques not only make processed surfaces more uniform and visually pleasing, but also help to differentiate them aesthetically through wide ranges of colours and matt, textured or glossy effects.

In addition, coating can improve the performance of plastic products by increasing resistance to wear, UV degradation and chemical agents, thereby extending their service life.

Technological innovations and sustainability in processing

Optimising plastic coating processes reduces waste and environmental impact, while achieving the desired aesthetic and functional quality. This means leveraging solutions that combine precision with high production efficiency. The keyword is therefore automation.

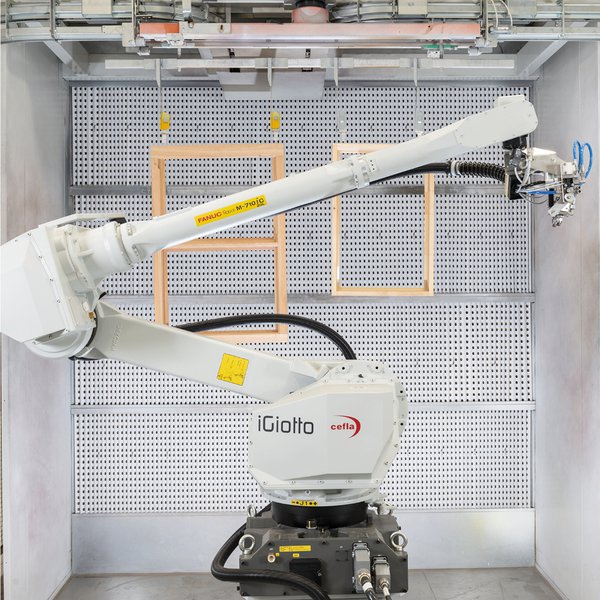

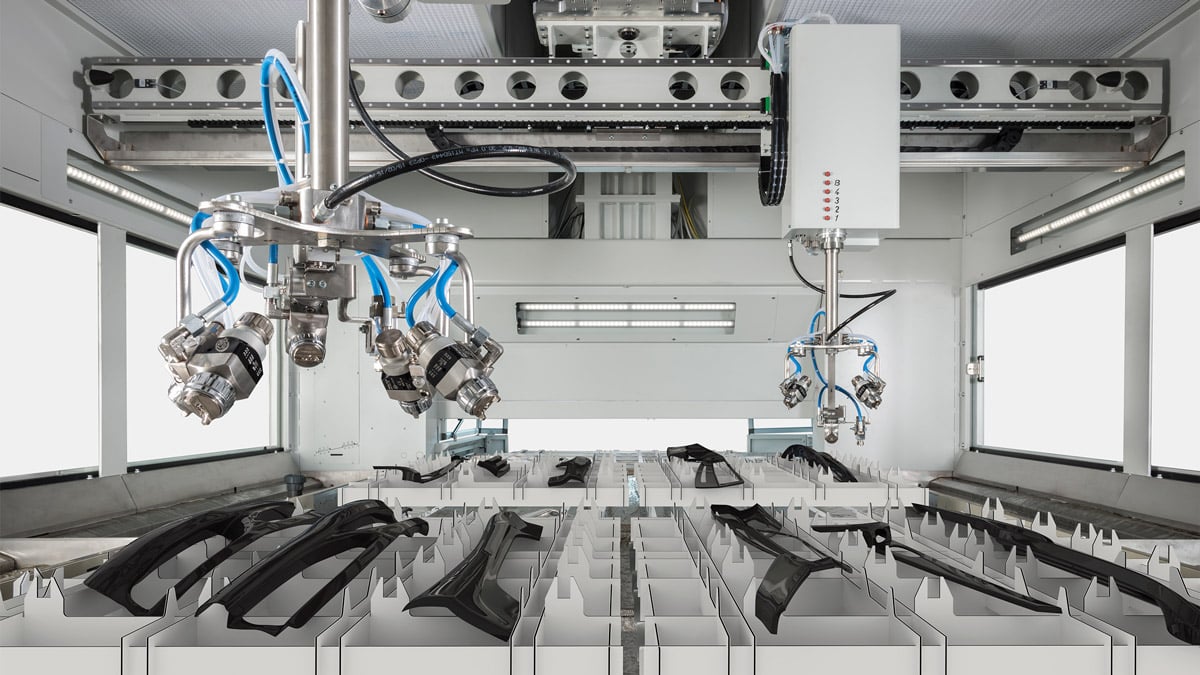

Drawing on decades of experience alongside plastic processing specialists, Cefla Finishing has designed and built automatic lines that address production scenarios in an innovative way.

Examples?

- Coating of car interior parts in glossy black (piano black) and silver, on an automatic line supplied by Cefla Finishing for a major German OEM. Here, coating improves the aesthetic appearance of parts and their resistance to scratches and abrasions, through the use of dual-cure lacquers (UV and thermal curing). The line includes all systems required for part cleaning, a Cartesian robot (iBotic) for coating, a multi-deck flash-off oven, a UV oven and a vertical oven for final curing. Designed to achieve both high quality and high productivity.

- In eyewear finishing: in the Cefla-designed line, different frame components are fixed to a rotating support beneath a series of spray guns, then coated at high speed while overspray is removed via a water-filtration system.

- For a completely different type of object: polypropylene flower pots. Cefla’s spray coating solution employs a high-performance anthropomorphic robot, iGiotto. The system works in two stages: pots, fixed to rotating spindles on a floor-mounted conveyor line, are first subjected to flaming – a crucial step to ensure correct paint film adhesion. Next, the pots move along the line for the second stage, spraying, performed by a second iGiotto. Drying is then completed in a hot-air tunnel. A fully automated procedure that saves time, reduces paint consumption and guarantees every pot a durable, high-quality finish.

Cefla Finishing, the ideal partner for improving plastic processing

Thanks to continuously evolving machines and a 3,000 sqm laboratory, Cefla Finishing can adapt every technology to most market use cases, offering customised solutions.

When it comes to coating plastics, Cefla’s modular approach to developing integrated lines and its expertise built alongside leading companies make it the ideal partner for this delicate process.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR FINISHING LINE?