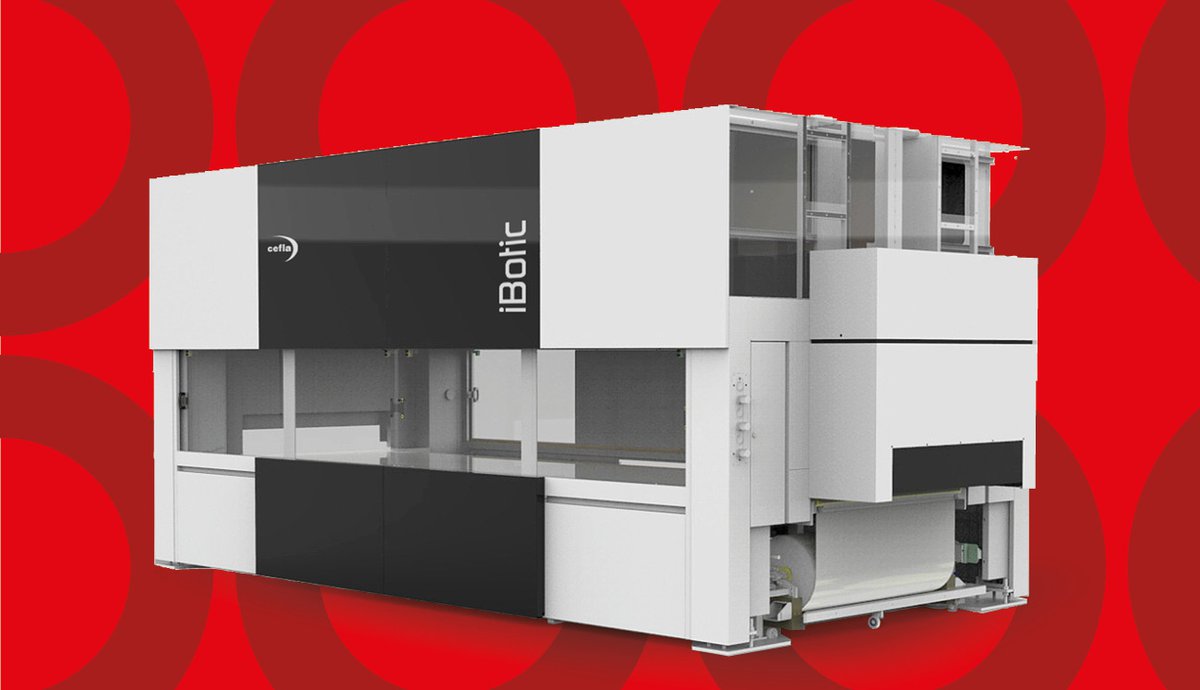

15 years after being launched in 2006, iBotic has undergone some major improvements which will maximise your uptime, reduce your operating costs as well as your lacquer and solvent costs, and with a brand new interface and integrated software, allow you to train operators in no time and access key production data directly on the machine or by feeding it into your company ERP.

Despite being a solution which has no rivals currently on the market, with its two spray arms acting totally independently to boost production efficiency and deliver the highest quality coating, iBotic benefits from a series of updates, fine-tuning and additional functions which enhance its appeal as a high-performance machine.

Brand new interface

Thanks to a new HMI with intuitive commands, user-friendly graphics and a software integration to help operators manage the equipment, iBotic is now easy to use with little initial training needed. Moreover, the software includes diagnostic tools, information to support maintenance requirements, valuable production data which can be consulted directly or fed into the company ERP for productivity analyses.

Zero downtime while changing colour

The key innovation enables on-the-go colour changeovers without interrupting production. While one arm is automatically set aside for cleaning and colour change, the second arm continues to spray workpieces without stopping. This keeps your production running and adds more or less 90 minutes per shift (we assume you avoid thirty 3-minute downtimes for colour changeover on each shift) to your effective production time, accelerating the ROI. Clearly, without production stoppages, you are constantly earning money rather than just changing colours. TIMESKIP also handles cleaning procedures in such a way as to reduce solvent consumption and cut lacquer wastage.

Energy recovery system to reduce operating costs

Our POWERBACK energy recovery system accounts for a 15-20% energy saving. This lowers operating costs and contributes to increasing your overall sustainability, environmentally and economically.

So, whoever thought it would have been difficult to improve iBotic, consider the benefits that are now available: zero downtime for colour changeovers, increased productivity, lower operating costs, less solvent and less lacquer wastage, plus a new HMI to support operators and optimise the process.

Cristian Giovannini

Product Manager | Spray Coating and Drying Technologies

Product development, technologies and machines for spray coating