Video

Focus On

TIMESKIP is the exclusive, patented, optional device which eliminates downtime for colour changeovers, without stopping production, granting substantial extra production time per shift and ensuring reduction of product waste. TIMESKIP allows for changeovers on one arm while the other arm can safely continue coating, without any risk of cross contamination.

Description

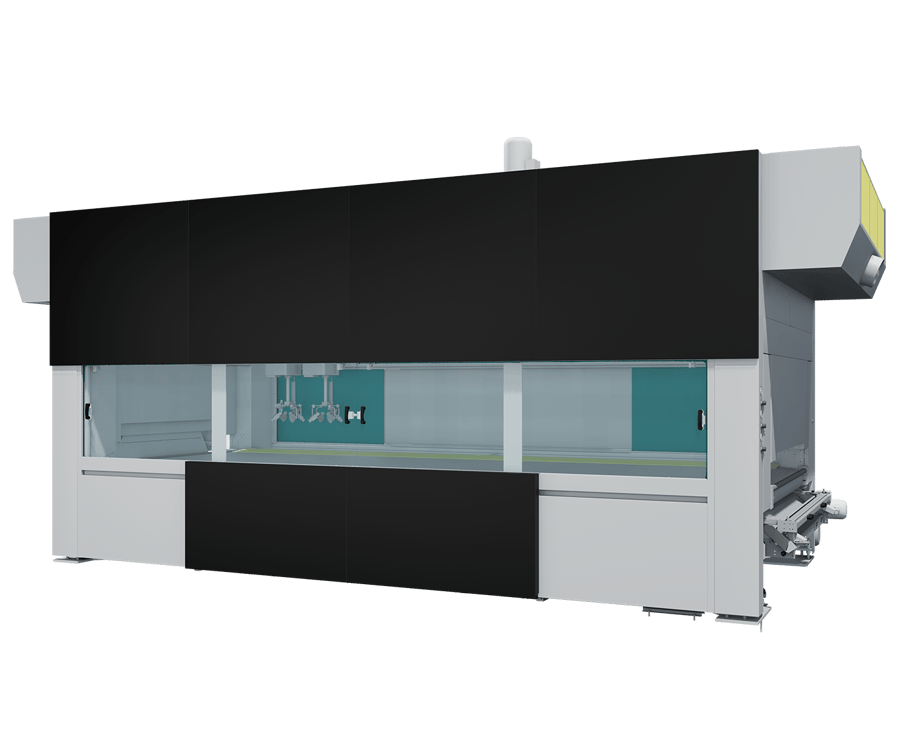

15 years after its introduction, iBotic is still the number one Cartesian spraying robot, but with a host of new features able to increase greater efficiency both in economic terms and in production terms, especially in view of customisation demands and consequent frequent colour changeovers.

What makes iBotic so special is that it can work simultaneously on pieces of different shape and thickness, with the conveyor either at standstill or on the move, in tracking mode. iBotic is also available in different versions with a working length from 3,000 mm* up to 5,500 mm*.

* Depending on the setting of the guns, the type of arm and the type of application, paint or glue.

Characteristics

- Improved hardware control reducing the equipment’s energy consumption

- Intuitive HMI graphics based on user feedback acquired over the years

- Simultaneous function control on the same arm for quicker adjustments

- Automatic adjustment system for the exhaust fan with less need for operator intervention

- Solvent trays are now accessible from the side of the machine

- Internal camera for monitoring purposes or remote servicing/troubleshooting by our technicians

Details

The reading barrier, available in 2D version with 512 photodiodes and latest-generation 3D C-Vision version, ensures high-definition workpiece shape, size and position acquisition, enabling the control software to plot the best spraying trajectories.

iBotic can be equipped with carbon fibre conveyor belt (CFB) or paper conveyor.

The CFB configuration is ideal for guaranteeing paint recovery (thanks to the recovery and cleaning carriage), minimal solvent consumption and shorter maintenance times.

The paper configuration is recommended for non-recoverable paint or glue finishes. The roll of paper, on high-capacity reels, has an electronically controlled pay-off, take-up and tensioning system.

iBotic can be equipped with an easily maintained and replaced two-stage paper filter (unique solution for glue application), or a water curtain filtration system, particularly recommended for finishes of the highest quality.

It also features a multiple output Plenum and fans to control the ventilation flows in the application zone. To guarantee the highest finish quality, the air can be treated by independent fans installed on the body of the machine or, in more complex lines, by external pressurisation and/or humidification units, also useful for serving the drying ovens.

For iBotic, Cefla Finishing has developed exclusive, state-of-the-art software able to decide and control all robot movements, from the simplest sequence of operations to the most sophisticated processing. This special control software allows user-friendly setting of all parameters.

What does it mean? Some mechanics improvements. More control of the arms movements, less vibrations. Less mains power consumption. Power Back retrieves energy from the machine’s decelerating spray arms so it can be re-used.

- SPRAYING ARMS: 1 or 2

- READING BARRIER: 2D or C-Vision 3D

- CONVEYOR SYSTEM: CFB or Paper

- OVERSPRAY FILTRATION: dry or water

- POWERBACK retrieves energy from the machine’s decelerating spray arms so it can be re-used

- Different working lengths