Here you can find articles on technologies, innovative techniques, and tips to improve the efficiency of your finishing line.

Article

How important are finishes for household appliances? More than one might imagine. Many actually underestimate this aspect. But the truth is that the objects we use every day—such as televisions, washing machines and refrigerators—owe many of their qualities to advanced finishing processes.

High-quality finishes and attractive, durable household appliances form an inseparable combination. Coating solutions make the difference, creating surfaces that are pleasant to the touch, long-lasting and visually impeccable, yet also capable of adapting to modern design requirements. All this without ever compromising functionality.

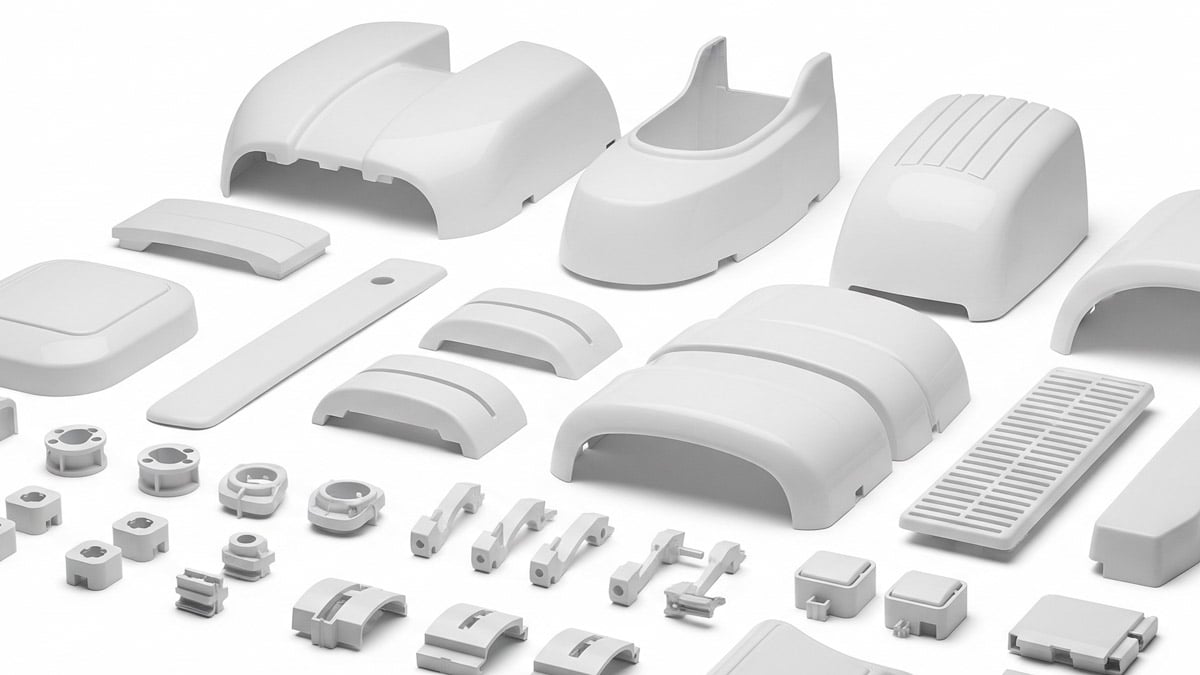

Let us consider the plastic parts forming essential elements of everyday objects, such as the bezel of an ultra-flat TV, the handles of refrigerators and ovens, or the porthole of a washing machine.

These are all components with two features in common: they must be aesthetically pleasing and, more importantly, safe and functional.

From this perspective—beyond basic engineering and design—the type of finish makes all the difference in the daily user experience. Handling, grip, perceived solidity and quality, and even the sense of seeing and touching something familiar and pleasant: all derive from the care with which finishes are applied to household appliances.

Objects that withstand the test of time can be recognised immediately. And it is precisely this feeling that most attracts consumers when making their purchasing decisions.

The only way to achieve such results is to rely on advanced spray-coating systems: composite and integrated finishing lines equipped with machinery capable of ensuring consistent quality at every stage of the process.

Cefla Finishing offers two dedicated solutions—iBotic and iGiotto App—which can also be integrated into existing coating lines.

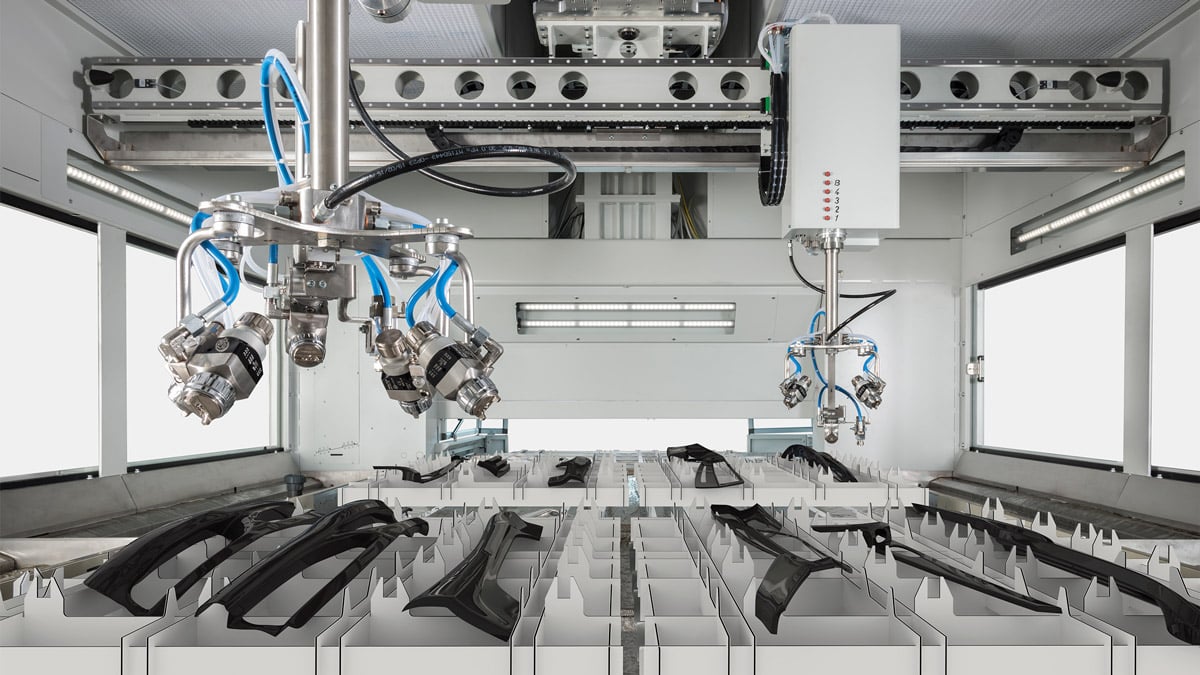

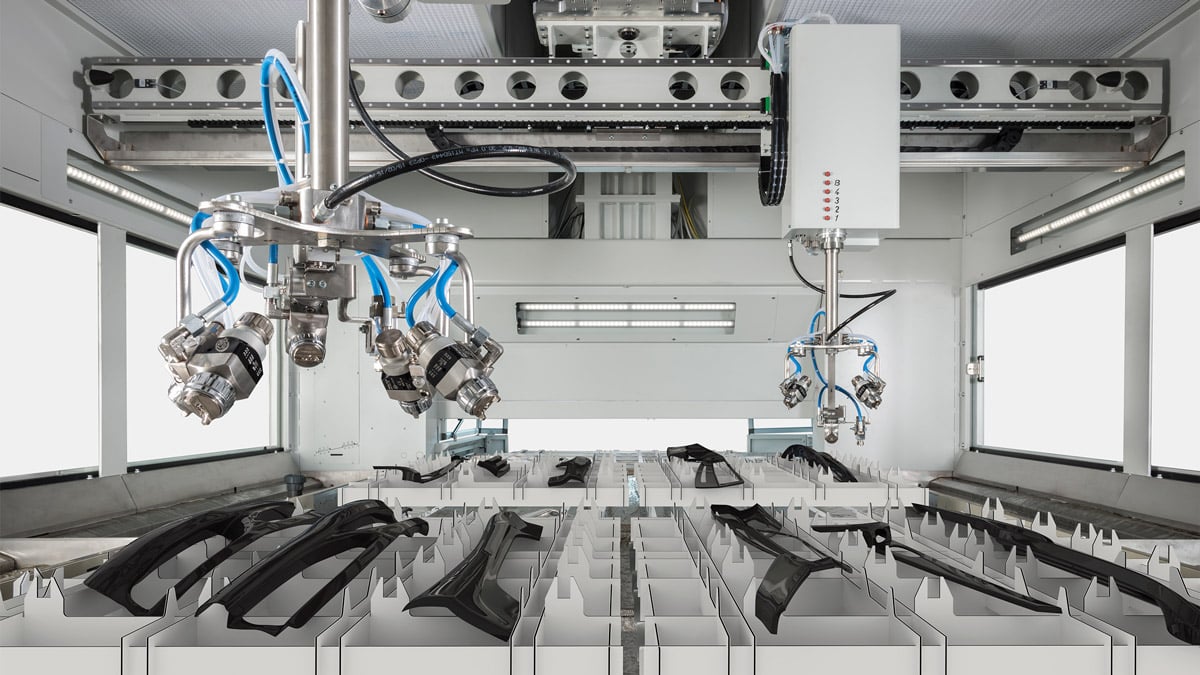

iBotic is a Cartesian spraying robot offering new functionalities to optimise coating operations for appliance components, with tangible economic and production benefits. The machine is ideal for companies dealing with increasing customisation demands, requiring frequent colour changes. What truly sets iBotic apart is its ability to work simultaneously on parts of different shapes and thicknesses, both at a standstill and in motion, in tracking mode, and to autonomously generate ideal spray trajectories through a 2D or 3D reading system.

iGiotto App is the automatic system that combines state-of-the-art coating technologies with the high performance of six-axis anthropomorphic robots. Equipped with cVision 3D, iGiottoApp can accurately detect the position, size and shape of incoming items, autonomously generating spray paths even for heterogeneous pieces with pronounced three-dimensional shapes. In short, everything needed to achieve maximum quality for every appliance component.

THE MOST INNOVATIVE FINISHING SOLUTIONS

Discover new finishing solutions: more effective, more productive and more competitive than those currently used by the industry.

Appliance finishes: every component requires its own treatment

Finishing household appliances may require different treatments to make the product more attractive to the end customer.

Take, for example, washing machine portholes: the part to be coated is the round chrome section surrounding the transparent window.

Chroming requires application on a prepared surface that covers defects and stresses typical of plastic parts produced through injection moulding. These defects—even when small—become highly visible once chrome is applied, especially when deposited in thin layers via PVD (Physical Vapour Deposition). Coating the component prior to chroming isolates the plastic substrate and covers imperfections, achieving significantly better aesthetic results and, above all, consistent long-term quality.

Base coating as preparation for subsequent chroming can be carried out on a Cefla line composed of cleaning and deionisation systems, an Easy-type sprayer, an Ecogel tunnel for paint levelling and a UV oven for final curing.

Cefla also provides all systems needed to prevent surface contamination from airborne dust, ensuring high-quality results.

This is why we have developed a modular range of coating solutions. For us, modularity is synonymous with personalisation: machinery and software can be integrated with maximum ease; existing lines can be modified simply by replacing or adding machines to completely change the process, increase productivity, handle batches of different sizes compared to the current plant, or introduce new coating cycles. This allows appliance manufacturers—operating in an increasingly dynamic market—to remain agile and responsive to customer demands.

It should now be clear that finishes for household appliances represent a key element in combining aesthetics and durability, enhancing perceived product quality.

By offering cutting-edge technologies—from reciprocating spray systems like Mito and Easy to robots such as iBotic and iGiottoApp—Cefla Finishing stands out as the ideal partner for implementing reliable, customised coating solutions for household appliances.

Contact us to learn how to continuously improve your finishing process: our experts are ready to interpret your needs and work with your technicians to develop a tailored solution.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR COATING LINE?

Article

More and more manufacturers are choosing to install industrial spray coating systems within their finishing lines. Precision, flexibility, reliability and efficiency are, after all, the watchwords of a technology that, thanks to automation, can be adapted for a myriad of applications and sectors.

Naturally, to maximise output, it is fundamental to design plants and processes that take into account the unique features of the machinery and to integrate them according to production goals.

But what does it take to plan an evolutionary path that is consistent with your growth strategy? Which solutions are best to adopt to meet the needs of your specific sector?

To answer this question, we have prepared a complete guide to the techniques, equipment and use cases that revolve around the subject of industrial spray coating.

Let's start by framing the topic from a technical point of view. Industrial spray coating is a manufacturing process that involves applying liquid or powder coatings to surfaces using specialised spray equipment. Unlike more traditional methods (for example, dip, brush or roller coating), industrial spray coating atomises the lacquer into fine droplets that are then transferred onto the substrates. This achieves rapid, uniform coverage on large and complex surfaces. (To learn more about this topic, we have dedicated an entire White Paper to the subject of painting complex shapes.)

Returning to industrial spray coating, the dynamics of this technology vary depending on the application for which it is implemented. In general, spray coatings provide smooth, glossy finishes for a wide range of manufactured goods, from consumer products to vehicle components, to furniture and furnishing accessories. Some coatings are formulated to perform specific functions, such as thermal insulation, electrical conductivity or non-slip properties. But there are even more particular use cases, such as the aerospace industry, as the technique, when applied with suitable materials, offers effective protection against corrosion, wear, chemical exposure and environmental factors, significantly extending the service life of products.

Industrial spray coating is increasingly valued as it supports mass production with consistent results, reduces labour costs and allows for precise control over coating thickness. Its versatility, as we will see, makes it suitable for a wide range of substrates, from metals and plastics to concrete, and for various applications.

DISCOVER THE MOST ADVANCED FINISHING SOLUTIONS

Elevate your competitive edge.

Industrial spray coating offers numerous advantages over other finishing methods. Firstly, as mentioned, its application versatility makes it possible to easily coat complex geometries, intricate components and large surfaces uniformly, a result that is difficult to achieve, for example, by brushing or dipping. This flexibility is essential for production lines that must handle objects with irregular three-dimensional shapes, such as car body panels and interior elements of motor vehicles.

But, compared to other approaches, spray coating also ensures greater performance in terms of speed and efficiency. The process can indeed be automated, which ensures high productivity and consistent results. Within a custom-designed line, spray painting can rapidly cover large surfaces, drastically reducing delivery times for large batches.

Among the plus points of industrial spray coating, one has to mention the uniformity of the applied material layer; atomisation guarantees a homogenous coating thickness, regardless of the coating material used. And, still on the subject of consumables, the wide range of materials compatible with spray coating – epoxies, polyurethanes, acrylics, zinc-rich primers and powders – allows for the creation of tailor-made solutions based on specific functional requirements:

This is thanks to the ability to control the desired thickness with extreme precision, which allows manufacturers to optimise material usage and meet its performance standards.

So, in brief, the advantages offered by industrial spray coating are:

Obviously, the choice and correct use of the most appropriate technique are fundamental to achieving the optimum result. Understanding the operating principle of each approach – which naturally has its advantages and disadvantages, and which is therefore more or less suitable for certain applications – is the prerequisite for maximising the performance of the coating materials on the objects to be treated.

Here is a quick reference guide to the most common painting techniques, all of which are covered by Cefla Finishing technologies and machines, with advanced and customisable solutions.

The most basic technique uses compressed air to atomise the coating material as it exits a spray gun. In its simplicity, it guarantees excellent coverage and is extremely versatile even when using different coating types. The approach, common in general finishing operations, vehicle painting and architectural coatings, has two potential disadvantages: overspray and higher material consumption which, if not properly managed, can lead to unwanted waste.

To overcome the limits of conventional spray coating techniques, companies can turn to HVLP systems, which use a high volume of air at low pressure to produce extremely fine droplets with a controlled spray. The technique thus offers superior transfer efficiency and reduces overspray, making it ideal for precision work, furniture finishing and touch-up applications. However, you might experience a slower transfer speed for thicker coatings.

This approach relies on high-pressure pumps to force the coating through a nozzle without compressed air. It provides rapid coverage for large surfaces, such as industrial tanks or structural steel. The main advantage of airless spray is its high productivity; however, it can produce overspray and may not guarantee optimal finish control.

This procedure, as the name suggests, combines the two aforementioned techniques (airless and conventional), using low-pressure air to further atomise the coating and improve the quality and control of the finish. Machines of this type are suitable for creating coatings that require a smooth, high-quality surface.

By electrically charging the coating particles, it is possible to attract them to the surfaces to be treated, ensuring greater transfer efficiency and minimal waste. Electrostatic spraying is therefore ideal for handling objects with complex shapes, such as vehicle panels and large metal structures. The resulting coating is excellent, with a drastic reduction in overspray. The main challenge in implementing this approach is the cost of the equipment and its maintenance.

The knowledgeable use of various industrial spray coating techniques allows for the adoption of a wide range of coating materials, each suitable for specific applications. Let's see which are the most common:

At the heart of an efficient, high-performance line, there is, of course, reliable and robust industrial spray coating equipment, designed to ensure quality and safety within increasingly integrated and automated processes. Here is an overview of the essential components for each of the techniques we have seen so far.

To be selected based on the chosen technique, spray guns are divided into different categories: compressed air guns for conventional methods, HVLP guns for precision work, air-assisted guns, airless guns and finally, electrostatic guns.

We are talking about pumps (piston, diaphragm or centrifugal) and pressure pots, which supply the coating material consistently and at the desired pressure. For dispensing powder coatings, there are specialised feeders capable of ensuring a constant flow.

Essential for resisting chemical attack and pressure fluctuations, high-performance hoses connect the pumps to the spray guns.

Depending on the type of application and material used, the guns are equipped with nozzles of different sizes and designs, which influence the spray pattern and material atomisation. Knowing how to choose the correct option is fundamental to obtaining uniform coatings.

Compressors, filters and dryers ensure a supply of clean, dry and regulated air, which is essential for achieving consistent spray quality and ensuring the longevity of the equipment.

Abrasives, detergents and primers, to be applied to substrates before spraying operations, are fundamental for ensuring optimal adhesion and coating performance.

These machines not only help to reduce overspray but also to control the fumes generated by spraying, helping to keep work environments safe. Operating in tandem with adequate filtration mechanisms, they minimise the environmental impact and health risks for coating operators.

For those working in close contact with industrial spray coating equipment, respirators, gloves, overalls and protective goggles remain essential to avoid contact with particles that are hazardous to the skin and respiratory system.

This guide to industrial spray coating can only conclude with an overview of the most popular applications in an ever-growing number of sectors. We are talking about extremely heterogeneous sectors, each with specific requirements, but all distinguished by a common need: to achieve maximum production efficiency without ever compromising on the quality of the finished product, the safety of their employees and eco-sustainability.

While in the automotive sector these techniques have been used for years for painting car bodies and applying clear coats and protective finishes, ensuring both pleasing aesthetics and corrosion resistance, in the aerospace sector, spraying allows aircraft components to be coated with specialised, lightweight and high-performance paints.

The marine industry is also discovering its advantages: the application of antifouling paints and protective coatings helps ships and offshore structures to resist microorganisms and the constant corrosive action of salt water.

Those in the manufacturing industry, on the other hand, use spray painting to apply protective and decorative coatings to machinery, domestic appliances and consumer products, while in the construction sector, the technique is used to coat structural steel and concrete surfaces or fibre cement elements with oxidation-resistant paints and protective layers.

With the aim of obtaining high-quality finishes on wooden and metal furniture, combining durability and pleasing aesthetics, the world of furniture and domestic appliances is also experiencing the benefits of industrial spray coating first-hand.

Then there are use cases that could be defined as extreme, such as applications in the heavy machinery and Oil & Gas sectors: industrial spray coating is currently the best option for creating coatings capable of protecting pipelines, offshore platforms and storage tanks from corrosion and chemical attack. Thanks to the use of zinc-rich primers and epoxy coatings, these treatments help equipment to withstand environmental damage, wear and chemical exposure, even over a very long period of time.

Each of the aforementioned sectors can, of course, only unleash the full potential of industrial spray coating when it designs and implements customised coating solutions, that is, ones capable of adhering to industry standards and the requirements imposed by clients. This is why it is essential to be able to rely on a partner like Cefla Finishing: our offering is constantly evolving, and aims not only to provide the market with a high-level technological supply, but above all to build, together with our customers, solutions capable of successfully tackling new and increasingly challenging use cases.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR COATING LINE?

Article

In recent years, industrial innovation has revolutionised the concept of surface finishing. Industrial roller coating has established itself as an efficient and versatile technology for companies focused on quality and productivity. This guide explores the advantages, processes, customised solutions, and the latest applications made possible by Cefla Finishing technologies.

Industrial roller coating is an application technology that employs sets of specialised rollers to apply lacquers or other coatings onto different types of substrates. More than a simple technology, it is a method widely used in production processes to ensure uniform, efficient, and high-quality finishes.

As the name suggests, the main component of a roller coating machine is the roller itself, a cylindrical tool designed to rotate and transfer the coating material onto surfaces. Rollers can be covered with different materials such as rubber, polyurethane, sponge, or silicone, each chosen according to the specific requirements of the application. Soft rubber rollers, for example, offer excellent elasticity and adhesion, making them suitable for treating irregular surfaces. Polyurethane rollers, on the other hand, provide durability and chemical resistance, particularly when more aggressive lacquers are used.

The operation of industrial roller coating solutions involves a combination of movements aimed at applying the lacquer and pressing it onto the material to be treated. This synergy produces a smooth and uniform finishing layer, though the result may vary depending on several factors. The type of roller coating material and its surface structure significantly influence the final appearance of the workpiece, which may feature glossy, matt, or textured finishes depending on the chosen solution.

Let us now look more closely at the advantages these techniques offer, and how Cefla Finishing’s innovative solutions — starting from soft rollers — help leading players across various industries position themselves on the market with products of impeccable quality.

Industrial roller coating is a technique with deep roots in traditional finishing approaches. Significant technological advances in recent years have revolutionised its role, expanding its uses and significantly increasing the efficiency of the machines.

Firstly, new-generation solutions allow uniform application not only on flat objects, but also on complex or irregular surfaces, reducing material waste and ensuring consistent finish quality by eliminating defects typical of traditional techniques, such as streaks or uneven coating layers, which are costly and time-consuming to correct.

Machines in the past were often unable to apply sufficient pressure to panels during coating. Operators were unable to control the process satisfactorily, and the poor quality of the result was only noticeable at the end. In addition, the application heads did not work on poorly calibrated panels or uneven surfaces. Manual cleaning of the machines was also time-consuming and costly.

Today's solutions overcome these limitations, improving operational performance and increasing application speed without sacrificing quality. Faster processing times translate into higher productivity and reduced labour costs.

Last but not least is the issue of sustainability: the new machines reduce VOC emissions and optimise resources, resulting in lower lacquer usage and energy consumption.

THE MOST INNOVATIVE FINISHING SOLUTIONS

Discover the most advanced finishing solutions to boost competetiveness.

The industrial roller coating process involves several stages, each of which is essential for achieving optimal results. A typical line involves six steps:

Each stage is crucial: incorrect preparation can compromise adhesion, while inadequate polymerisation can lead to premature wear. A well-orchestrated process ensures a durable finish, optimising production and reducing waste.

Moving from theory to practice means evaluating various parameters and understanding what upgrades to make to your systems. Choosing the ideal industrial roller coating solution requires a comprehensive analysis of multiple factors.

Knowledge of the operating environment is essential. Applications exposed to high temperatures, humidity or chemicals require specific properties in the coating and rollers. The material to be treated (metal, plastic, wood, composites) determines the choice of roller and coatings. Mechanical loads, operating speed and type of finish influence the selection process.

Budget, machine life, maintenance costs and energy requirements also play a role in the choice: modular solutions help to evolve according to needs.

Other technical criteria: system efficiency, low material consumption, compliance with environmental regulations (e.g. low VOC).

Efficiency, ease of use, accessibility and control of the machine process are also fundamental. The user interface must be intuitive even for inexperienced operators, and maintenance/cleaning operations must be quick.

Finally, real-time or remote monitoring should not be overlooked: constant control, intuitive interfaces and easily controllable functions are required.

Cefla Finishing takes care of every aspect of the design of its solutions, helping each customer to maximise efficiency and optimise resources based on real business needs.

Standard offerings are not always sufficient for complex industrial applications. Customised roller coating solutions allow you to meet specific operational requirements. A customised approach adapts the line to particular materials, surface geometries and environments.

By developing tailor-made solutions, companies gain better control over the application and reduce waste. A customised roller coating system can optimise thickness on delicate (up to 0.3 mm) or intricate surfaces.

Investing in these solutions also means equipping yourself with future-proof technologies: modular systems can be upgraded as production grows through targeted revamping, ensuring sustainability and operational flexibility even in the medium to long term.

Customised solutions are a strategic choice for those seeking operational excellence, cost rationalisation and technological innovation. Cefla Finishing acts as a consultant and partner, not just a technology supplier.

Cefla Finishing's expertise and capacity for innovation are embodied in Smartcoater PRO, the industrial roller coating machine designed to meet the needs of modern finishing lines.

Equipped with four screw jacks for a rigid structure, Smartcoater PRO is able to exert greater constant pressure on the panels. The integrable pneumatic floating system allows lateral movement of the application head, compensating for irregularities or poor panel calibration.

The result is uniform coating and a drastic reduction in waste. Thanks to its soft rubber application roller, Smartcoater PRO can also perform operations such as base coat coating on raised panels with shallow grooves, minimising paint consumption compared to traditional spray application while maintaining precision and speed.

With Smartcoater PRO, hybrid lines can be installed: two roller coating stations and a spray coater for the finishing layer. This offers benefits such as:

Industrial sectors that benefit from specialised roller coating

Advanced technologies such as Smartcoater PRO are extremely versatile and applicable in many sectors:

In the wood industry, precise coating ensures aesthetics and durability for furniture and accessories. In the steel industry, roller coating allows for protective and decorative applications against corrosion and wear. In printing, paper and packaging, uniform applications guarantee print quality and product protection.

In textiles, roller coating adds water resistance and special textures. The automotive and aerospace sectors are also increasingly using this technology to meet safety and performance standards.

Cefla Finishing offers tailor-made solutions for all these markets, providing its expertise for innovation and customisation at the highest levels.

ARE YOU LOOKING FOR THE IDEAL SOLUTION FOR YOUR ROLLER COATING LINE?

Article

Time is running out to replace curing lamps containing mercury. Starting in just a few months, the EU will gradually introduce a ban on the manufacture, import, export and use of UV lamps with mercury. You may even find it already hard to procure replacement lamps for your drying equipment and the situation certainly will not improve as we near the end-of-year deadline.

Let’s start by saying that the news is good! Developed at our LAB, also supported by our LED technology experts from C-LED, we have developed different innovative solutions that will comfortably replace your mercury lamps.

These new LED lamps have been tested by independent paint manufacturers, all successfully. We have already set up a number of solutions in our laboratory, so that you can test your products and verify the results.

WHITE PAPER: FROM UV-R TO UV LED

A practical guide to replacing traditional mercury vapor UV-R ovens with high-efficiency, sustainable UV LED solutions.

In just a few months it may be too late to conveniently replace your mercury lamps. First because they will become difficult to obtain, second because it’s always a good idea to arrange things in advance. The replacement that our technicians take care of will be customised to suit your line.

We are here to help you avoid lost production and we are here to provide you with a highly efficient solution that will:

Article

Industrial ovens are essential components of the finishing process. These machines ensure the drying of paints and coating materials applied to substrates.

There are in fact several types of industrial ovens, each designed not only according to the desired finish, but also in relation to the lacquer required to achieve it: in order to generate high-quality, long-lasting results, the industrial oven must meet specific curing parameters.

It is therefore essential to understand in detail what the production requirements are and to choose solutions that meet them, ensuring the right balance between costs, efficiency and performance.

Here are Cefla Finishing’s suggestions for evaluating the technologies currently available on the market.

What, first of all, is an industrial oven, and what features must it have to perform its role in the finishing process? We are talking about a specialised heating device, designed to process large quantities of materials or products in controlled thermal environments.

Unlike domestic ovens used for cooking or baking, the industrial oven, which operates in much more demanding environments, must guarantee long operating life and high heating capacity while ensuring precise temperature control and sustainable energy consumption.

The basic operation of industrial ovens involves heat generation via electric resistances or fuel-powered systems, though there are also hybrid approaches and more advanced technologies. Once produced, the heat is transferred to the workpieces mainly by convection or radiation, depending on the type of oven. For example, convection ovens circulate hot air to distribute temperature evenly, while radiant ovens use infrared or ultraviolet elements to alter the state of surfaces.

Regardless of the heating system, temperature control remains fundamental. This is why industrial ovens are equipped with sophisticated sensors and monitoring and control systems, allowing operators to maintain constant operating conditions, which in turn ensure uniform results.

In some cases, the machines incorporate programmable logic controllers, enabling optimal execution of processes based on specific stages (such as drying, baking, curing or heat treatment), where even small temperature variations can affect the final result.

THE MOST INNOVATIVE FINISHING SOLUTIONS

Discover the most advanced finishing solutions to boost competetiveness.

Industrial ovens can be classified according to a multitude of parameters: from heating methods to energy sources, to design configurations. Let us take a closer look, highlighting the characteristics of the main categories.

Linear industrial ovens feature a horizontal configuration that enables continuous processing of workpieces along a production line. Thanks to the constant, controlled flow of hot air, they guarantee perfect drying and curing uniformity, reducing processing times and optimising energy consumption. This type of oven is ideal for applications on wood, glass and composite materials, where continuous production cycles and high-quality finishing are fundamental requirements for consistent, top-level results.

Vertical industrial ovens are characterised, as the name suggests, by their design, with a chamber that extends vertically. This system increases operational efficiency thanks to better space management, ease of loading/unloading and uniform heat distribution. This is why vertical industrial ovens are widely used in sectors such as ceramics and glass, where vertical orientation makes product handling easier and increases overall process consistency.

When UV lacquers are used, an appropriate curing system is needed, namely a UV oven. This technology ensures extremely precise processing and an eco-friendly process, since it requires far less energy than traditional systems.

In addition, with the new UV iCure technology, presented by Cefla at Ligna 2025, the use of mercury in UV oven lamps has been completely eliminated, in full compliance with European environmental and safety regulations. A solution that combines top-quality finishing results with a strong focus on sustainability, enabling companies to upgrade their lines without changing the lacquers in use.

Learn more on our page dedicated to replacing mercury lamps and in the white paper "From UV-R to UVl LED."

WHITE PAPER: FROM UV-R TO UV LED

A practical guide to replacing traditional mercury vapor UV-R ovens with high-efficiency, sustainable UV LED solutions.

Excimer Ovens represent the new frontier for manufacturers aiming to obtain ultra-matt surfaces, thanks to excimer technology.

Thanks to these technologies, capable of meeting highly diverse needs, industrial ovens have become indispensable in numerous sectors, including those with highly specific processing requirements.

In metallurgy, for instance, ovens are used for heat treatments such as annealing, tempering and hardening of steel and alloys to improve their mechanical properties and durability. In ceramics and glass processing, by contrast, they are mainly used for firing clay products and for glass tempering and annealing.

Companies in the electronics sector rely on industrial ovens for curing coatings, soldering and assembling components made from extremely delicate materials, which therefore require total temperature control.

It should also be remembered that in the food industry, processes such as cooking, drying, roasting and sterilisation are managed by specialised ovens that guarantee safety and preserve the organoleptic properties of processed products.

Finally, for those working in paints and coatings, these machines facilitate the drying and curing of paints, enamels and powder coatings to improve finishing quality and increase product durability. But the curing of composite materials is also essential in aerospace, automotive, sporting goods and furniture production.

Cefla Finishing has extensive experience serving all these sectors, continuing to develop advanced, integrable solutions to meet specific process requirements and evolving industry standards.

Investing in a modern industrial oven, on the other hand, offers numerous benefits. In summary:

Precise temperature control, uniform heat distribution and programmable cycles ensure consistent, high-quality results, reducing defects and rework.

In addition, careful management of cleanliness and air quality in the processing environment helps protect treated materials, ensuring flawless and consistent finishes in every production run.

Advanced ovens with automation features enable faster cycle times, higher production capacity and reduced downtime.

By integrating thermal insulation mechanisms, heat recovery systems and efficient burners, these machines significantly reduce energy consumption and operating costs, helping companies align with sustainability goals and market expectations.

The implementation of intelligent controls, sensors and data recording allows meticulous process monitoring, which can be optimised in real time.

New-generation solutions are designed to last: they exploit components that require less frequent maintenance and leverage modularity to facilitate part replacement.

Updated safety features and compliance with industry standards safeguard worker safety and ensure compliance with environmental and safety regulations.

Maximising these benefits means making a wise investment: choosing the most suitable industrial oven for your production requirements requires careful assessment. Several key factors determine a successful implementation. Cefla Finishing has identified eight, covering the full range of parameters to consider before investing in these solutions.

First of all, it is necessary to establish what the oven will be mainly used for: evaporation, drying or curing? Substrates, coatings and processes all imply specific requirements in terms of temperature, atmosphere and cycle handling.

Next, it is necessary to determine the maximum temperature required for processing, as well as the tolerance needed to maintain process consistency. Some applications demand minimal tolerance, while others can allow for a wider temperature delta.

It may sound obvious, but it is essential to assess the volume of products to be processed daily and the useful load capacity. Machine footprint, internal oven dimensions and the number of items it can handle per cycle must therefore be considered.

Different materials (wood, metals, ceramics, polymers) have specific thermal properties and sensitivities. It is therefore necessary to select an oven that takes into account the characteristics of the material and the required finish.

Based on the above considerations, one must choose between different heating systems: hot water exchangers, electric, gas or hybrid, depending on energy costs and supply availability, but also taking into account environmental regulations and the plant’s sustainability objectives.

This may seem like a reiteration of the previous point, but assessing the energy efficiency of an industrial oven is actually a subject in its own right. When choosing a solution that represents a long-term investment, it is strategic to consider all operating costs, including energy supply.

What, finally, is the desired level of automation throughout the process? Advanced oven models integrate PLC controls, sensors and data recording systems that help optimise operations and ensure repeatability.

Last but not least, the matter of financial resources. It is necessary to balance initial investment with operating costs, maintenance and expected service life: in this sense, high-performance ovens may involve a higher initial outlay, but a lower total cost of ownership.

Starting from the analysis of these factors to make an informed decision is essential when choosing an oven in line with production goals, budget and company growth plans.

That said, flexibility remains a fundamental characteristic in a market that requires the ability to manage small production batches without sacrificing the ability to scale when necessary. At Cefla Finishing we know this well, which is why we design and manufacture a wide range of finishing systems where modularity is a critical success factor: this is the only possible way to create solutions that can be extensively customised in relation to all the parameters just highlighted.

Choosing the most suitable solution for your needs is important, but so is a correct approach to maintenance. Compliance with safety protocols is also crucial to maintaining high efficiency and extending the service life of industrial ovens.

Regular preventive maintenance includes routine checks of electrical connections, heating elements, fans and insulation. Cleaning filters, replacing worn components and verifying control systems help maintain optimal performance and prevent failures, which inevitably lead to costly downtime.

Ovens, moreover, must be equipped with advanced safety devices, starting with emergency shutdown systems, thermal switches and over-temperature alarms. Adequate ventilation of the production areas is also essential.

At Cefla Finishing, we are committed to supporting customers even after the initial installation: we offer comprehensive after-sales services, including scheduled maintenance sessions, remote diagnostics and rapid technical assistance. It is therefore a genuine long-term partnership, ensuring that the purchased solutions remain reliable, efficient and safe throughout their operational life, minimising downtime and safeguarding workforce safety.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR COATING LINE?

Article

Plastic processing plays a crucial role in several industrial sectors: polymers make it possible to manufacture parts that are versatile, cost-effective, ergonomic and easy to assemble.

The main techniques used in plastic processing include injection moulding, extrusion, compression and thermoforming, each designed to produce specific shapes and functionalities. Increasingly common is the manufacture of carbon parts obtained by layering sheets inside a mould, followed by an autoclave forming process to achieve the desired component.

Increasingly so, coating is being added to these processes, through which paints or surface treatments are applied to enhance the appearance and performance of plastic items, making them more attractive or resistant to use.

Surface layers and protective coatings increase resistance to environmental factors and the overall longevity of the workpiece, making plastic suitable for an infinite range of uses.

The industrial applications of plastics are countless. Often chosen for their unique properties, plastics are used in strategic sectors such as automotive, aerospace and electronics.

In automotive applications, for interior and exterior coatings, injection-moulded plastics allow complex shapes to be created, integrating aesthetics with functionality while keeping operating costs relatively low. Plastics such as polypropylene, polycarbonate, ABS, polyurethanes and their combinations are used to produce components such as bumpers, dashboards and other vehicle parts.

The reasons are twofold: plastic materials not only enable aesthetically appealing parts to be produced, but they also reduce vehicle weight, improve fuel efficiency and reduce emissions, contributing to environmental sustainability and compliance with regulatory standards.

Fuel tanks are often made of high-density polyethylene, which ensures corrosion resistance while being lighter than traditional metal tanks. This choice improves vehicle safety, since plastic tanks are less prone to puncture and can be moulded into more complex shapes to fit specific designs.

The aerospace sector uses advanced composites, such as carbon fibre reinforced polymers, in structural components such as wings, fuselage sections and tail assemblies. These materials offer lightness and strength, improving fuel efficiency and aircraft performance.

Inside cabins, plastics and composite materials are used to manufacture seat parts, overhead bins and side panels: this choice also contributes to reducing overall aircraft weight.

In electronics, ABS and polycarbonate are commonly used to produce casings for smartphones, laptops and other small consumer devices. These materials offer durability, impact resistance and ease of production, also enabling elegant and distinctive designs.

Even circuit boards benefit from plastic processing: in particular, laminated plastics are used as substrates for printed circuit boards thanks to their excellent dielectric properties, which favour the miniaturisation of electronic devices.

Main techniques of plastic processing

In each of the sectors mentioned above, plastic processing is carried out using different techniques. Among the most widespread methods, as mentioned, are injection moulding, extrusion and thermoforming, each offering specific advantages depending on the desired output.

Injection moulding is a widely used technique involving the pressurised injection of molten plastic into a mould cavity. This process allows for high precision and large-scale production of complex shapes; it is ideal for manufacturing intricate design items such as car parts and household objects.

Extrusion, on the other hand, involves forcing molten plastic through a shaped die capable of creating continuous profiles such as tubes, sheets and profiles.

Thermoforming is a technique that uses heat to soften plastic sheets, allowing them to be moulded into specific shapes using dies. Thermoforming is a more economical process than the previous ones, given the lower cost of the dies, and is therefore suitable for producing small batches or large parts.

DISCOVER THE MOST ADVANCED FINISHING SOLUTIONS

Elevate your competitive edge.

Once the parts are produced, the coating phase follows. This is a crucial process in plastic processing, as it significantly enhances the aesthetic and functional qualities of the final product, adding value even to low-cost items and increasing their perceived worth.

Coating and surface treatment techniques not only make processed surfaces more uniform and visually pleasing, but also help to differentiate them aesthetically through wide ranges of colours and matt, textured or glossy effects.

In addition, coating can improve the performance of plastic products by increasing resistance to wear, UV degradation and chemical agents, thereby extending their service life.

Optimising plastic coating processes reduces waste and environmental impact, while achieving the desired aesthetic and functional quality. This means leveraging solutions that combine precision with high production efficiency. The keyword is therefore automation.

Drawing on decades of experience alongside plastic processing specialists, Cefla Finishing has designed and built automatic lines that address production scenarios in an innovative way.

Examples?

Thanks to continuously evolving machines and a 3,000 sqm laboratory, Cefla Finishing can adapt every technology to most market use cases, offering customised solutions.

When it comes to coating plastics, Cefla’s modular approach to developing integrated lines and its expertise built alongside leading companies make it the ideal partner for this delicate process.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR FINISHING LINE?