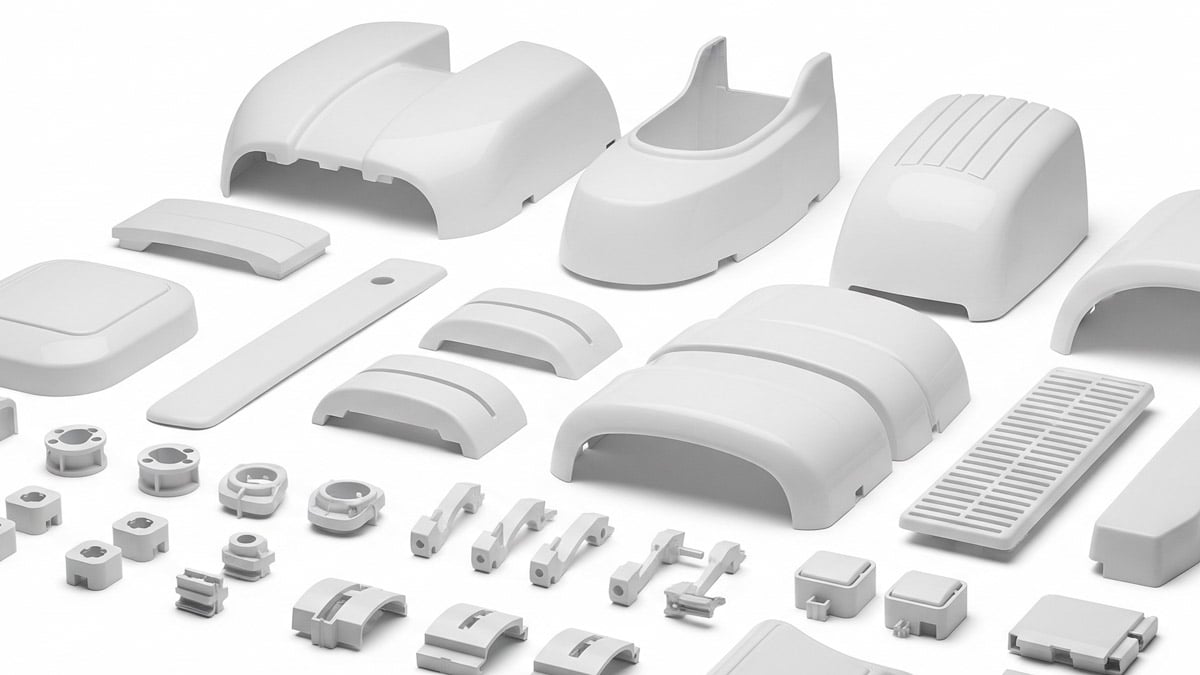

Coating: the most important phase in plastic processing

Once the parts are produced, the coating phase follows. This is a crucial process in plastic processing, as it significantly enhances the aesthetic and functional qualities of the final product, adding value even to low-cost items and increasing their perceived worth.

Coating and surface treatment techniques not only make processed surfaces more uniform and visually pleasing, but also help to differentiate them aesthetically through wide ranges of colours and matt, textured or glossy effects.

In addition, coating can improve the performance of plastic products by increasing resistance to wear, UV degradation and chemical agents, thereby extending their service life.

Technological innovations and sustainability in processing

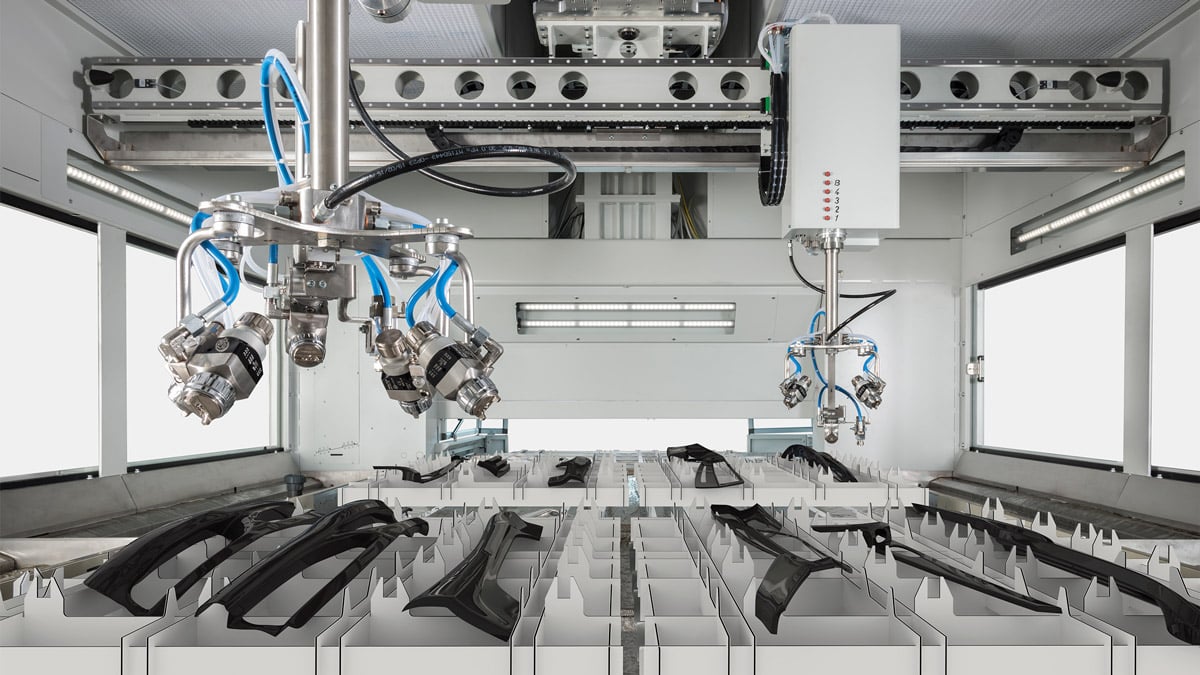

Optimising plastic coating processes reduces waste and environmental impact, while achieving the desired aesthetic and functional quality. This means leveraging solutions that combine precision with high production efficiency. The keyword is therefore automation.

Drawing on decades of experience alongside plastic processing specialists, Cefla Finishing has designed and built automatic lines that address production scenarios in an innovative way.

Examples?

- Coating of car interior parts in glossy black (piano black) and silver, on an automatic line supplied by Cefla Finishing for a major German OEM. Here, coating improves the aesthetic appearance of parts and their resistance to scratches and abrasions, through the use of dual-cure lacquers (UV and thermal curing). The line includes all systems required for part cleaning, a Cartesian robot (iBotic) for coating, a multi-deck flash-off oven, a UV oven and a vertical oven for final curing. Designed to achieve both high quality and high productivity.

- In eyewear finishing: in the Cefla-designed line, different frame components are fixed to a rotating support beneath a series of spray guns, then coated at high speed while overspray is removed via a water-filtration system.

- For a completely different type of object: polypropylene flower pots. Cefla’s spray coating solution employs a high-performance anthropomorphic robot, iGiotto. The system works in two stages: pots, fixed to rotating spindles on a floor-mounted conveyor line, are first subjected to flaming – a crucial step to ensure correct paint film adhesion. Next, the pots move along the line for the second stage, spraying, performed by a second iGiotto. Drying is then completed in a hot-air tunnel. A fully automated procedure that saves time, reduces paint consumption and guarantees every pot a durable, high-quality finish.

Cefla Finishing, the ideal partner for improving plastic processing

Thanks to continuously evolving machines and a 3,000 sqm laboratory, Cefla Finishing can adapt every technology to most market use cases, offering customised solutions.

When it comes to coating plastics, Cefla’s modular approach to developing integrated lines and its expertise built alongside leading companies make it the ideal partner for this delicate process.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR FINISHING LINE?