Challenges and standards of coating in the aerospace industry

The aerospace industry has always relied on high-quality coatings for its aircraft, regardless of whether they are aeroplanes, helicopters or even satellites. The coatings for these vehicles must withstand extreme environmental factors. This is why aircraft coating is not merely an aesthetic operation – for the creation of attractive liveries, for example – but represents a critical component in ensuring performance, safety and the long-term durability of the aircraft. Not least, it is necessary to comply with the stringent regulatory requirements governing the sector.

Corrosion

One of the requirements of aircraft coating is corrosion resistance. Aircraft, and helicopters in particular, are exposed to humidity, salt and other corrosive elements during service, especially in coastal or humid environments and in relation to areas of the aircraft that cannot be easily accessed, such as the inside of the wings. Studies conducted on commercial fleets show that adopting more controlled and repeatable coating processes, such as automatic processes, significantly reduces maintenance costs and downtime, ultimately extending the service life of the fleet.

Weight

Weight control is another critical factor to consider in the aircraft coating phase. Aerospace industry players are under constant pressure to improve fuel efficiency, which requires reducing weight without compromising structural integrity. Coating using automatic systems ensures uniform application because the speed of the spray guns and their distance from the components are constant; it is therefore possible to guarantee the thicknesses required by specifications, avoiding thickness – and therefore weight – increases that can occur when coating is carried out manually.

Extreme temperatures and ultraviolet rays

Finally, there are extreme temperature variations and exposure to ultraviolet rays. During cruising, aircraft operate at altitudes where temperatures can drop to -60°C with exposure to high levels of ultraviolet radiation, while during take-off and landing they face elevated temperatures. Thermal expansion and contraction cycles, as well as ultraviolet exposure, cause paint delamination problems, which must be addressed through accurate control of the coating process in all its stages.

Advanced technologies for aircraft coating plants

Just as aerospace companies constantly push beyond their limits in terms of aircraft design, those who, like Cefla, develop coating solutions for aircraft are equally aware of the importance of innovation.

Automated coating systems have revolutionised the process of applying coating materials, ensuring uniform coverage and high-quality finishes that meet the stringent requirements of civil and military aviation. Self-programming robotic arms for spraying, increasingly accurate in their movements, are able to maintain constant speeds and application angles, significantly reducing the risk of error and improving the uniformity of treated surfaces. Automation is also essential for achieving the desired film thickness, a crucial aspect for the durability of internal and external aircraft components.

The adoption of IoT devices in aeronautical finishing departments enables continuous monitoring of critical environmental parameters, allowing immediate interventions to optimise plant performance and prevent defects. Integrated within the Industry 4.0 paradigm, these technologies enable seamless communication between systems, supporting advanced analysis, predictive maintenance and data-driven decision-making. The result is an overall improvement in operational efficiency, with reduced costs and waste.

Requirements

Requirements of finishing solutions for the aerospace industry

The requirements for aircraft coating solutions depend on the type of application. According to the intended use of the components to be processed, coated and finished, the preferred approach also varies. Structural components, for example, have very different needs compared to interior coatings or externally positioned parts. Below are a few examples.

Executive jet interior fittings

The premium aesthetic and tactile characteristics required for the interior components of a private executive jet can be achieved using different technologies, all suitable for personalised decoration if required.

Scratch-resistant finishes

Using excimer matting solutions, it is possible to obtain scratch-resistant soft-touch finishes on flat and shaped panels with shallow grooves.

Aircraft structural parts

Producing structural elements that meet extremely high standards requires meticulous control over coating thickness and weight tolerances, achievable both with flatbed lines and traditional (overhead or floor-fixed) lines.

Aircraft overhead bins

Attention to final quality and colour-related aspects is of primary importance for the visible surfaces of aircraft overhead bins: spray coating is the usual choice when seeking to achieve this result.

Finishing technology applications for the aerospace industry

Aerospace finishing technologies can be used for different components, made of carbon fibre, aluminium or other high-tech materials.

A vast range of raw materials are used, as well as a number of technologies including:

Technologies

Application fields

Below are some aerospace industry specific application areas and finished products:

APPLICATIONS

Executive jet interior

Aircraft structural parts

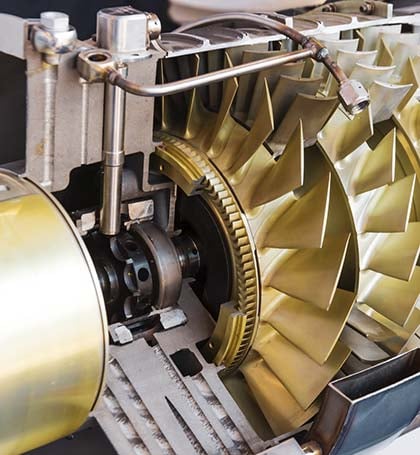

Mechanical parts and hydraulic circuit components

Aircraft overhead compartments

Surface treatment plants in the aerospace sector

Although each family of aerospace components requires specific approaches, all coating processes must guarantee impeccable quality, resistance to external agents, operational flexibility and maximum precision in application, also in relation to controlling the weight of each component.

What is required, from a technical standpoint and in terms of know-how, to create surface treatment plants that meet these requirements? If an advanced and integrated portfolio of solutions is the conditio sine qua non for designing a state-of-the-art automatic coating line, achieving the high quality standards demanded by the market means relying on a partner capable of supporting the transition from manual to automatic application over time, assisting the customer throughout the training phase, commissioning, and subsequently throughout the entire lifetime of the plant.

The Cefla Finishing offering has been conceived with the precise objective of responding to these needs, providing those operating in the aerospace supply chain not only with innovative technologies but also with consultancy and after-sales services.

Our advanced coating systems are designed with a modular logic, which allows finishing lines to be adapted to the specific needs of the customer and customised with tailored solutions, even in the presence of existing plants. This approach makes it possible to achieve exactly the desired result for both external surfaces and interior aircraft components.

Focus On

The advantage of testing new solutions, as AVIO has done

Implementing automation requires an in-depth understanding of the process being transformed. In the aerospace industry, this means carefully studying each task, verifying every process variable and establishing the correct parameters for setting up the machines.

This is why companies in the aerospace sector that turn to Cefla Finishing are offered the opportunity to test equipment and software through practical use cases set up within our laboratories in Europe, Asia or the United States. In this way, solutions can be fine-tuned even before being installed in their final plants.

A concrete example is AVIO, an Italian company specialising in rocket launchers. With the aim of industrialising the process, we jointly designed an automated line to optimise the application of a special coating on thermal insulation materials.

The result was precise grammage control, excellent thickness uniformity and a 30% reduction in coating consumption, with tangible advantages in terms of product quality and cost savings.

Find out which machines can help you create components for the aerospace industry

Machines

Case studies

Case study

WHITEPAPER

Want to know how to save time, materials and worries?

Download our white paper and learn about our paint recovery system.

Download the White Paper!

Learn More

MAGAZINE

For sixty years we have been innovators in the field of surface finishes.

With our innovative technologies, software and IoT solutions, we are the ideal partner for aerospace industry players.

Feel free to contact us to visit our 3,000 sqm laboratory and test your own components on our industrial equipment.

Contacts

Frequently Asked Questions

Frequently Asked Questions

High flexibility in terms of output rate and choice of cycles/processes according to the line make-up.

Zero solvent emissions thanks to 95% use of products with high dry residue (UV) content.

Possibility of using the roller technique for any application on all flat surfaces.