Drying: what is an industrial oven for?

Based on the characteristics of the finished product, a coating oven must guarantee an optimal result. For example, the use of latest-generation industrial drying ovens makes it possible to:

- obtain fast and uniform drying

- take up little space, thanks to compact and vertical solutions

- obtain specific aesthetic finishes (deep matt, etc.)

- implement "green" and energy saving processes (for example in the case of UV ovens)

In some cases, heated rooms with forced ventilation are used as an alternative to ovens to speed up the drying process.

In which industries are coating ovens used?

Campi di utilizzo

The following is a selection of specific products finished in industrial ovens

APPLICATIONS

Panels

Stairs

Ceramic panels

Interior components

Furniture components

Wooden components

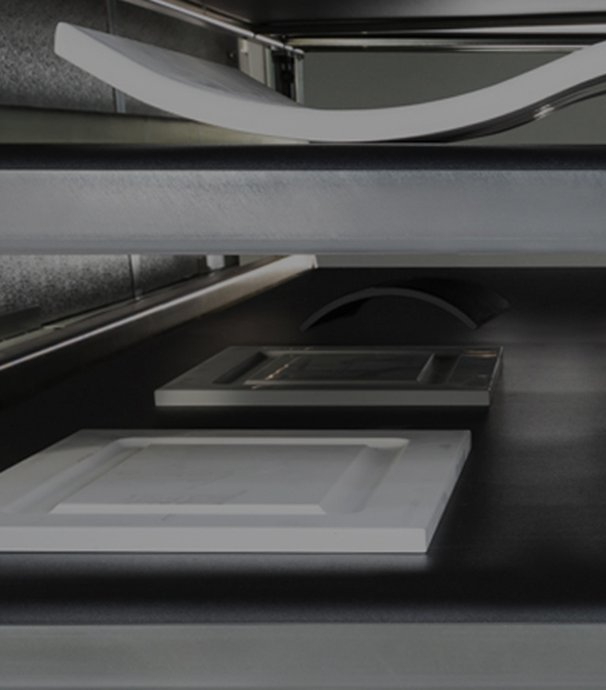

What are the existing types of coating oven?

These coating ovens are integrated in finishing lines designed primarily for water-based lacquers. The ovens in this category are Aquadry and Ecogel. We also supply ovens for glass panels and in-line ovens for profiles.

A vertical oven is designed to dry pieces that require long hold times in a controlled and clean environment. Omnidry belongs to this category.

When UV paints are used, an adequate drying system is required. UV ovens guarantee sustainable drying, because of lower energy consumption. The UV-R, UV-R LED and UV-I ovens belong to this category.

For deep matt finishes, excimer matting ovens are used to obtain matt-finished surfaces based on patented technologies. The Exydry oven belongs to this category.

Focus On

Drying ovens: flexibility is the word

Flexibility is a key feature in a market that requires small production batches without, however, compromising on productivity. At Cefla, we develop a wide range of finishing systems, using water-based or solvent-based lacquers and 100% UV acrylic paints. We can provide customised solutions to meet all customer application needs - ranging from energy efficiency to size requirements.

Discover Cefla Finishing drying solutions

MACHINES

Case studies

Case study

Webinar

Learn more about UV-I in our webinar

Learn More

MAGAZINE

Are you looking for the ideal solution for your coating line?

All you have to do is fill out the form and contact us to obtain support from our experts.

Connect

Frequently Asked Questions