A game changer: No more machine downtime for Pianca thanks to automatic colour changeover

PROJECT DETAILS

Customer:

Pianca

Country:

Italy

Media Video:

About the customer

Pianca was established in 1956 to quickly rise to leadership status in the furniture industry. Specialised in the creation of systems and furnishing accessories for residential environments, both for the sleeping area and the living area, Pianca has an approach to design focused on the customisation of products and spaces, aimed at meeting the style requirements of flexible, mobile and change-oriented living.

The challenge

Pianca successfully partnered with Cefla Finishing to maintain its signature extreme customisation while at the same time increasing productivity - which was negatively affected by frequent colour changes. The company's production strategy focuses on "Batch 1": this approach means that each piece is unique and requires personalised settings and extremely frequent colour changeover.

The Cefla Finishing solution

The new coating line replaced three obsolete systems, centralising the coating process in a single high-performance line. To address the customer's brief, i.e. improve productivity and efficiency, Cefla experts have implemented innovative solutions allowing to significantly reduce machine downtime and automate processes previously performed manually.

Results

The new finishing line allows the processing of small batches and single workpieces, dramatically reducing - or eliminating altogether - machine downtime. Pianca has thus managed to achieve the same or even better standards of quality, customisation and flawless service, while cutting production costs. The company now has satisfactory margins to continue to provide an excellent product and service at competitive prices.

A game changer: No more machine downtime for Pianca thanks to automatic colour changeover

"The challenges that Pianca posed to us spurred us to come up with the best system that could help them achieve their objectives."

Cristian Giovannini

Product Manager - Cefla Finishing

Pianca is an industry player capable of skilfully combining industrial expertise and craftsmanship - topped with passion, Italian design and a solid corporate identity. However, to preserve the manufacturer's authenticity and continue to offer quality as well as customisation, innovation had to be introduced. Production had to change, for everything to remain the same and true to its nature.

The price of customisation

Pianca, with its furnishing accessories, is committed to meeting the needs of a lifestyle based on flexibility, mobility and change. These priorities are at the very core of its production. In an industry where uniqueness is an increasingly valuable asset, eternally in contrast to price, the ability to offer an endless range of colours and finishes, even for single pieces, is hugely appreciated. This strategy has significantly contributed to Pianca's success and to the strengthening of its leadership in the global market, becoming key to its modus operandi.

However, the market scenario became even more challenging when increasingly competitive prices, and not just product uniqueness, started to be a precondition. How is it possible to develop an efficient industrialised production process when, in actual practice, large-scale production is not applicable?

Cefla technologies combining productivity and customisation

The weak link in Pianca's production chain was the colour changeover process. Having to frequently stop the line to produce many different small batches hugely affects production efficiency. That's why optimising the colour changeover process was key to making a huge impact on Pianca's productivity.

Cefla Finishing technicians have studied a way to apply Cefla's innovative solutions capable of reducing machine downtime to the new plant. One of these is Timeskip, the patented device allowing the line robot to continue coating with one arm, while the other arm can carry out colour changeover or maintenance operations.

The more efficient management of colour changeover, however, did not happen at the expense of product customisation, which, on the contrary, was further maximised. Stefano De Meio of Pianca's Industrialisation & KPO Office mentions among the advantages obtained the possibility of achieving extreme customisation through endless colour combinations and even sample colours, in addition to minimising or eliminating altogether the time needed for changing colours on the machine, with a substantial reduction of downtime.

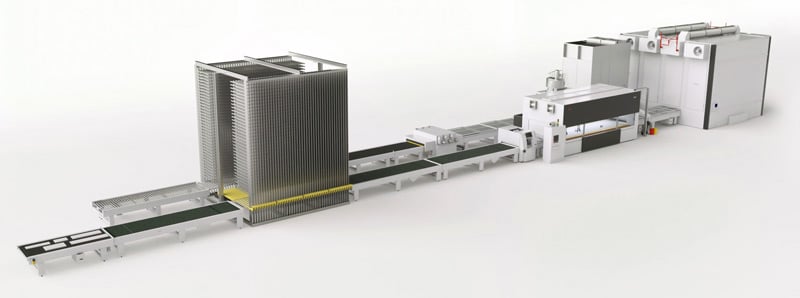

As many as three old Pianca lines replaced by the new system

Thanks to the new technologies introduced, the new Pianca plant has revolutionised the company's finishing process and has replaced three distinct finishing lines, optimising finishing in a single production cycle. The line is equipped with:

- An automatic warehouse performing multiple functions:

- Line feeding buffer, designed to store the material to be coated, to then independently feed the line without needing any supervision by human operators;

- Material storage, to reduce colour changeovers on the return line;

- Line unloading buffer, if operators are temporarily unavailable for these operations.

- The line also consists of an automatic material reading and identification system. The colour request is sent via a QR code scanner to the coating robot. The scanner is able to read the labels on each workpiece to be finished.

- The 2-arm coating robot is the core part of the coating process. The two arms are able to operate independently and carry out colour changeover operations without stopping production on the line.

- A vertical oven is integrated into the line to complete the material drying cycle.

- Finally, the system is equipped with line software, to make line management easier in consideration of the degree of complexity linked with frequent customisation requirements.

Sustainability and lower consumption

From a sustainability point of view, the new coating plant allows waste to be minimised, both in terms of downtime and in terms of product loss. The ultimate goal is to achieve greater productivity and a faster return on investment. The implementation of Timeskip and the integration with a mixing and colour changeover system not only reduce downtime, but also contribute to limiting paint waste, both during colour changeover and in terms of waste product disposal after each operation, resulting in lower waste management costs.

The partnership with Cefla Finishing

The partnership and mutual trust established between Pianca and Cefla Finishing were the pillars underlying the successful implementation of the new production line. The manufacturers strongly believed in their partnership with Cefla, acknowledged as the ideal industry player to meet their needs in terms of quality, reliability and productivity.

A crucial success factor was the prompt assistance received during the early stages of system implementation. The professional and timely management of requests by the Cefla Finishing team has significantly strengthened a relationship based on trust. Stefano De Meio highlighted the exceptionally positive human relationship and effective communication with Cefla, both from a commercial and from a technical point of view.

In conclusion, Pianca expressed the strong feeling of security deriving from its collaboration with a highly organised group like Cefla Finishing, and confirmed that all expectations have been fully met.

“I would recommend Cefla to any company that is looking for productive dynamism, champions innovation and is after a well-structured and reliable partner.”

Stefano De Meio

Industrialisation & KPO Office - Pianca

Project Gallery