How can simple materials be transformed into elegant, functional and customised creations? This is one of the most fascinating challenges in the furniture and construction industries. In this article, we will explore two of the key technologies in the decorative finishing sector: wrapping and lamination. These techniques are not only fundamental for aesthetics, but also represent a turning point for operators in the sector, in terms of efficiency and sustainability. So let's find out how the two techniques differ and what the latest technological innovations are that are redefining the possibilities for the industry.

What is wrapping?

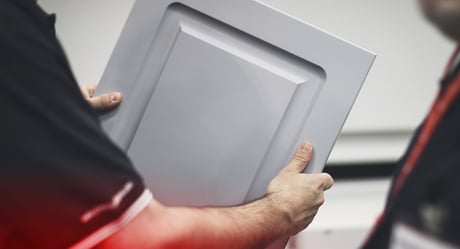

Wrapping, or profile covering, is a technique that has revolutionised the way we think about decorative finishes. Imagine being able to coat linear profiles such as wood, PVC or aluminium with high-quality decorative materials. This process, carried out with specialised machines, applies the coating material to the substrate using hot-melt adhesives.

But what are the real advantages that wrapping brings to companies? In addition to cost-effectiveness (coating less valuable materials allows for an excellent aesthetic and functional result at a lower cost), wrapping offers a degree of production flexibility that allows for the application of a wide range of finishes and decorations. Furthermore, modern wrapping lines can reach incredible speeds, up to 110 m/min, ensuring high productivity. And with automation, set-up and format change times are drastically reduced, adapting perfectly even to smaller and customised production batches. It goes without saying that these aspects also affect production costs, and therefore we can define wrapping as a technique capable of perfectly combining quality, flexibility and production efficiency.

The role of profile wrapping in customised finishes

Have you ever wondered how some manufacturers manage to respond so quickly to the market's just-in-time demands? Profile wrapping is one of the answers. This technology, as mentioned, makes it possible to create components with a unique and elegant appearance, while maintaining high quality standards and low costs.

The real magic happens thanks to automated systems like RoboWrap from Düspohl - the Cefla brand specialising in wrapping technologies - which allow for very rapid format changes. And this means having a wide range of finishes and customisations, without compromising production efficiency. In short, in a world where customisation is increasingly in demand, modern wrapping technologies guarantee the necessary flexibility, without compromising on quality and durability over time.

A SHORT GUIDE TO PROFILE WRAPPING

What is lamination?

Let's now move on to explore another fundamental technology: lamination. But what is it exactly? Imagine applying a decorative sheet to a flat substrate, using presses or rollers that exert pressure and heat. This, in simple terms, is the process called lamination.

This technique is ideal for treating large flat surfaces. Commonly used materials include melamine sheets, PVC and high-pressure laminates (HPL). Lamination is widely used in the production of furniture and building components, thanks to its ability to ensure uniformity and resistance.

Flat lamination for large-scale production

What is the advantage of flat lamination in large-scale production? This technology is fundamental for managing large production volumes, often exceeding 50 m/min. But it is not just a question of speed.

Flat lamination makes it possible to obtain extremely resistant and durable finishes, which are essential in high-traffic environments or those subject to intense wear. Thanks to advanced pressure and temperature control systems, the entire finishing process becomes fluid and perfectly synchronised, improving efficiency and reducing waste.

Wrapping vs lamination: key applications in manufacturing

A question naturally arises: which of the two technologies should you choose? Wrapping and lamination, while sharing the goal of decorating substrates, are distinguished by their applications and processes.

- Wrapping is the technique used for finishing linear profiles and components with complex geometries, also adapting to small batches and frequent changes.

- On the other hand, lamination is used for treating flat and regular surfaces, ideal for mass production of large elements.

Both technologies play a fundamental role in customisation and efficient production.

|

Feature |

Wrapping |

Lamination |

|

Material compatibility |

PVC, foil, veneer |

HPL, melamine, acrylic |

|

Applications |

Profiles, decorative panels |

Flat panels, large surfaces |

|

Productivity |

High flexibility |

High-volume production |

|

Cost-effectiveness |

Cost-effective for small batches |

Ideal for mass production |

Materials used in wrapping and lamination

In both wrapping and lamination, the range of materials is vast and varied. Profiles in solid wood, MDF, PVC and aluminium are commonly used as substrates in wrapping, while chipboard and MDF panels prevail in lamination.

And for the coatings? PVC foils, decorated papers and CPL laminates in wrapping; HPL laminates and melamine foils in lamination. Every choice of material or adhesive has a direct impact on the quality and longevity of the finished product.

Innovations in wrapping and lamination

If the choice of materials is important and must be calibrated according to various factors, the choice of machines in the processes is essential and determines not only the quality of production, but the very business success of companies in the sector.

What are the most important innovations in the sector? Systems like Düspohl's RoboWrap in wrapping and the PowerWrap Wide in lamination are redefining the standards of efficiency and versatility. With the integration of AI and machine learning, these technologies not only improve the quality of the work, but also optimise energy consumption, reducing waste.

Sustainability in wrapping and lamination

It is no coincidence that innovations in wrapping and lamination are guiding the industry towards more green practices. In line with this global trend, Cefla Finishing and Düspohl solutions integrate systems aimed at reducing the environmental impact of production processes.

In the field of wrapping, new technologies are allowing for a more efficient use of materials. The precision of adhesive application systems, such as those used in RoboWrap, makes it possible to significantly reduce glue and coating material waste, with a reduction in waste of up to 30% compared to traditional systems. Furthermore, the optimisation of profile change processes reduces downtime and the associated energy consumption.

In the lamination sector, the PowerWrap Wide introduces technologies that allow the use of eco-sustainable materials. These include coatings based on recycled or biodegradable materials and adhesives with low VOC (Volatile Organic Compounds) content. And the impact on sustainability is far from marginal: the adoption of these materials can reduce the process's carbon footprint by up to 40%.

Another area of focus is energy efficiency: new AI-based control systems optimise energy consumption in real time, adapting process parameters to the specific needs of each job. This optimisation can lead to energy savings of up to 25%.

The durability of finished products is another aspect closely linked to sustainability. Advanced wrapping and lamination techniques are producing surfaces that are increasingly resistant to wear and tear, extending the useful life of products and reducing the need for replacement. This translates into lower resource consumption in the long term.

In short, the main focus is on the entire product life cycle: from production, to end-of-life recycling solutions, thanks to techniques that facilitate the separation of materials for recycling. This leads us to reflect on the need to adopt a circular economy approach, collaborating with suppliers and customers to implement systems for the recovery and reuse of waste materials.

These initiatives, promoted by Cefla Finishing through innovative solutions, not only reduce the environmental impact, but also offer economic advantages, demonstrating that sustainability and efficiency can go hand in hand in the manufacturing sector.

Looking to the future

Wrapping and lamination are undoubtedly technologies that are constantly evolving to respond to market challenges and sustainability needs. Looking ahead, a further integration of these technologies with Industry 4.0 is expected, with the incorporation of smart elements in finished products and an ever-increasing digitalisation of production processes.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR COATING LINE?