Today’s challenges are often connected to recurrent issues faced by a broad variety of manufacturing industries where a product undergoes a finishing process.

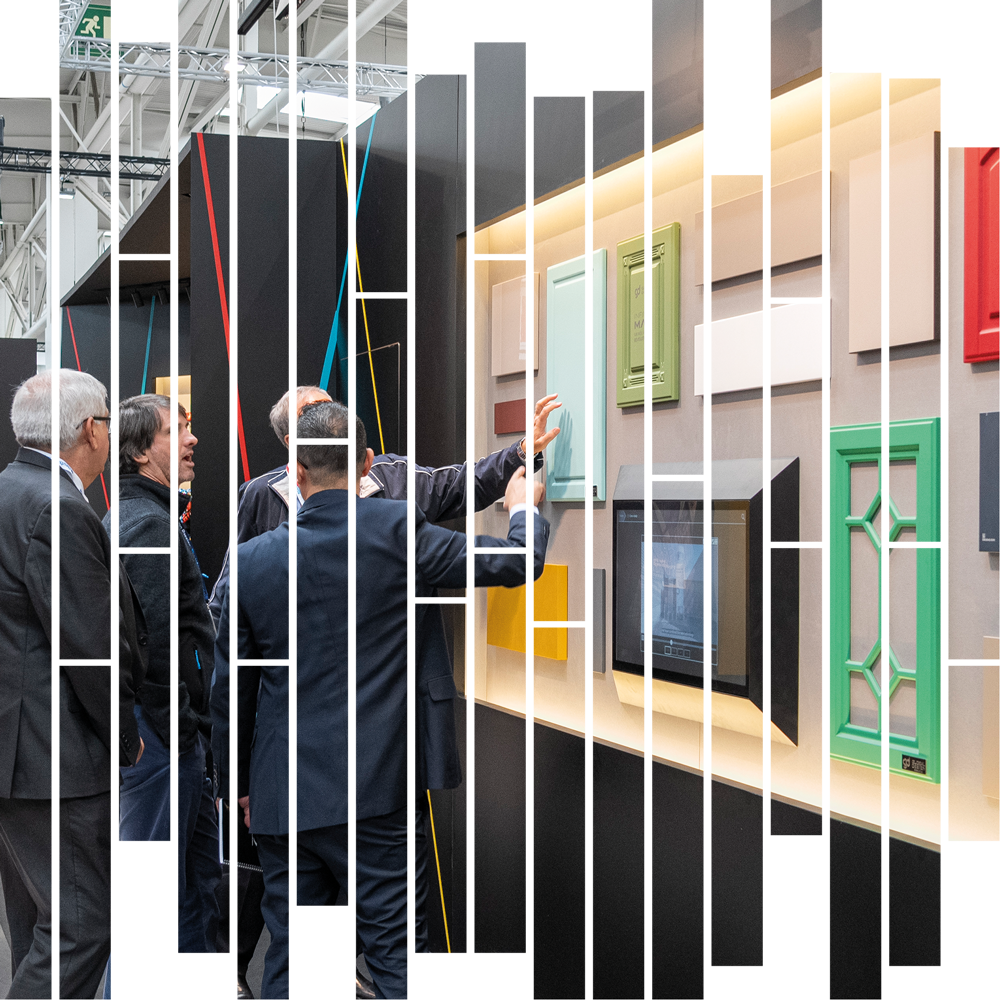

Wood and its derivatives are some of the most common substrates coated in the furniture and building sectors. At Ligna 2023, Cefla Finishing took a practical approach to present the best solutions to those everyday issues that concern finishing outfits across the globe.

JUST TO MENTION A FEW TOPICS WE ADDRESSED AT THIS EDITION OF LIGNA:

At Ligna in Hanover we demonstrated the latest innovations that will enable companies to implement colour changeovers without stopping production. Managed by a special software and a system which involves the equipment’s mixing valves, colour changeover requires less than 30 seconds compared to the standard 2 to 3 minutes needed today.

Running on our Easy spray coater, the Fast Colour Switch system (FCS) generated a great deal of interest as it was clear to visitors that considering standard shifts and colour changes, the FCS would reduce downtime by at least 30 minutes/ day or between 2 and 3 hours weekly.

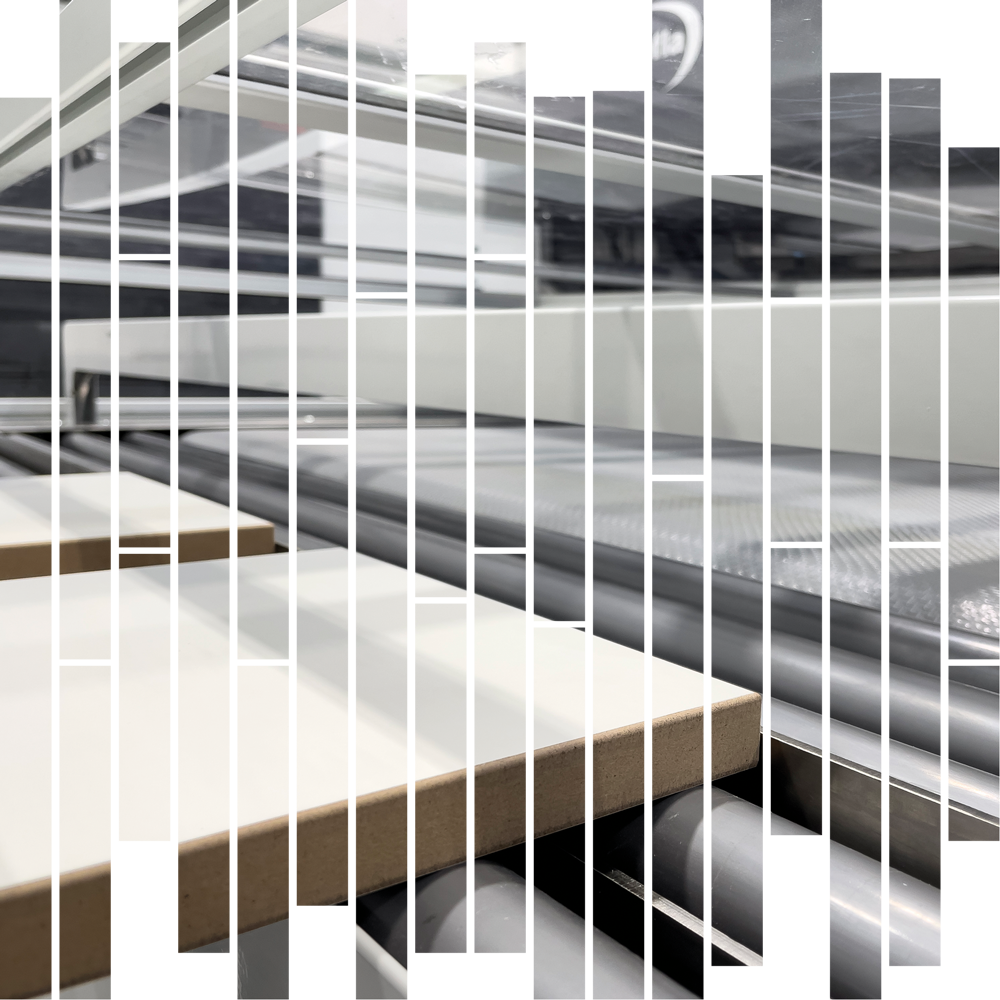

One way to obtain the perfect match between a panel surface and the panel’s edge is to use the very same technology for both parts of the process, vacuum coating technology. This is exactly what Cefla Finishing implements with two highly innovative machines built into a line featuring edge and surface coating equipment and sanding capabilities, all in a fully automated solution.

Demonstrated on a line incorporating our Smartvacuum coater and Smartedge, panels were processed from start to finish before visitors’ eyes. Thanks to the superior transfer efficiency ensured by vacuum coating technologies, lacquer waste and costs are significantly lower. Seen at Ligna: same lacquer, same technique, same finish. And what’s more, an invisible overlap seam.

Cefla’s profile wrapping brand Düspohl presented a line made up of optimised standard equipment that reduces set-up times, simplifies handling and minimises downtime. The line was equipped with special tools to wrap profiles with CPL surface material managing radiuses of up to 1 mm.

We privilege smart solutions that positively impact efficiency and output, with no more than a moderate investment. These can be completed with optional solutions for special applications or for automation purposes, the degree of which is scalable, depending on customer demands and project requirements.

Beyond the need for high-performance machinery, Cefla Finishing develops in-house software solutions to support companies embracing Industry 4.0. Created by a team of experts and suitable for use on hybrid lines integrating Cefla solutions and third party machines, these tools help customers achieve efficiency, reliability, predictability, and provide software for remote monitoring as well as line simulation for layout planning.

Monitoring and control potential was demonstrated using cMaster, a solution we developed to enable remote access to a production line without the need to download software. All you need is a stable web connection and a device (mobile phone, tablet or PC).

Small batches, tight deadlines, colours that change every few pieces, and what’s more, the market demands a deep matt finish. At Ligna, we showcased 2 innovations that respond to these demands: iBotic and Exydry-Z.

The new iBotic Cartesian spraying robot equipped with TIMESKIP, avoids downtime when you need to change lacquer. Using interpolated axes, so the two arms spray independently of each other, means you can immobilise one arm and change colour without interrupting production.

Further down the line showcased at Ligna, Exydry-Z processed flat and raised panels to obtain the soft-touch, scratch-resistant, fingerprint-proof deep matt finish the market is demanding. And with lower nitrogen consumption than comparable excimer matting technologies

In line with iBotic, we showcased our latest evolution in the range of brushing machines. Featuring a humidification system and transversal brushes, the Smartclean PRO is able to remove the finest dust particles and electrostatic charges from a flat or raised panel surface.

Raised panels such as kitchen cabinet doors usually undergo a spray coating process involving application steps for basecoats and topcoats, and subsequent curing. Sanding is also necessary and workers are involved with handling. Live at Ligna, our Smartcoater PRO was equipped with a soft rubber application roller and special features to handle raised panels with grooves up to 10 mm.

Visitors were particularly impressed by the reduction in lacquer consumption thanks to improved transfer efficiency, by the number of handling operations that could be saved by applying the basecoat on a roller coater, and the shorter time to market.