Finding a way to match the finishing quality of your flat surface with the edge, especially when the market is looking for rounded edges and flat surfaces as part of the latest furniture trends, means you need to consider using the same paint and the same technique. Until today, this was just theoretical, but since we introduced Smartvacuum to combine with Smartedge, our vacuum coating solution for edges, it is now a reality.

Vacuum coating: sustainable and cost-efficient

Depending on the production volumes, with vacuum application technologies there are different solutions to coat the surface and edge of a panel. Outputs up to 1500 cabinet doors/shift can be handled with an island-type process dealing with:

- melamine sanding

- flat surface coating (Smartvacuum)

- edge coating (Smartedge)

- sanding prior to finishing

In-line processes are better for outputs exceeding 3000 cabinet doors/shift and can be either:

- melamine sanding

- panel surfaces coated in the Smartvacuum area

- panel edges coated in a 2-step process with Smartedge

- sanding prior to finishing

or for 6000 cabinet doors/shift as follows:

- melamine sanding

- in-line flat surface coating (Smartvacuum)

- all 4 panel edges coated using Smartedge

- sanding prior to finishing

Both Smartvacuum and Smartedge use 100% UV acrylic paints, avoiding release of solvents into the atmosphere. Processing times are reduced compared to alternative application technologies and less space is taken up by these machines.

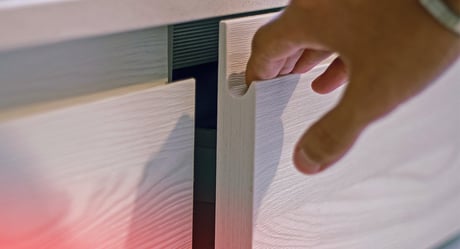

Focusing on the edge coating process, we have developed patented solutions for Smartedge which are unrivalled on the market. EDGE&GO enables line operators to switch from one edge geometry/thickness to the next in no more than 15 seconds.

The dual function sanding unit for vertical corners with a radius and the flat section of a J-pull ensures compliance with the original radius and sanding of the excess product at the leading and trailing end of the handle.

The paint removal and panel cleaning unit seals the melamine between the flat part and the edge, recovers excess applied product and creates a perfectly flat panel surface. This prolongs the life of the abrasive paper in contact sanding machines, as wear is homogeneous over the whole surface.

The winning duo

The combination of Smartvacuum and Smartedge finally allows companies to streamline their coating process using the same technique and delivering the same top quality all round. It avoids pollution compared to spraying lacquers with solvents, it speeds up the process, reducing the handling necessities and, above all, cuts costs significantly.