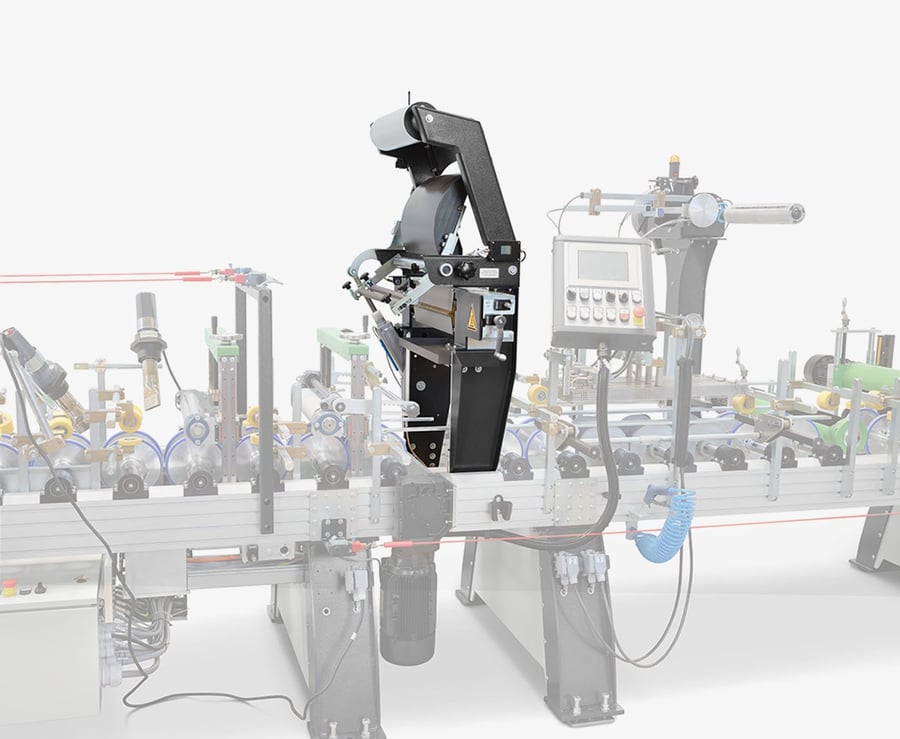

Focus On

Foil temperature is kept constant even at rapidly changing feed rates through automatic adjustment of the heated surface in contact with the foil.

Description

Preheating foil to its perfect application temperature not only helps conserve glue cost, but also enhances adhesive distribution and therefore increased wrapping quality! Düspohl’s foil heating system adapts automatically to variations in transport speed and works with all foil types and colors.Characteristics

- Heating not dependent on foil colour and structure

- Non-stick coating surface

- Low energy consumption

- Contactless foil temperature measurement remotely from the adhesive application unit

- No foil thermal deformation in case of machine stops

- No radiant heat/glare near the machine

- Pre-selectable foil temperature

- Can be retrofitted to all existing machines

Details

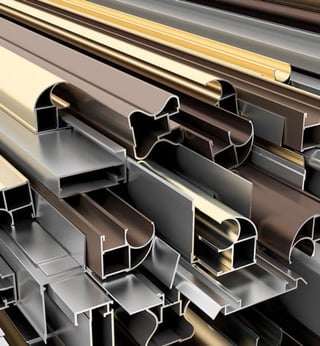

Materials

Plastic

Wood