Focus On

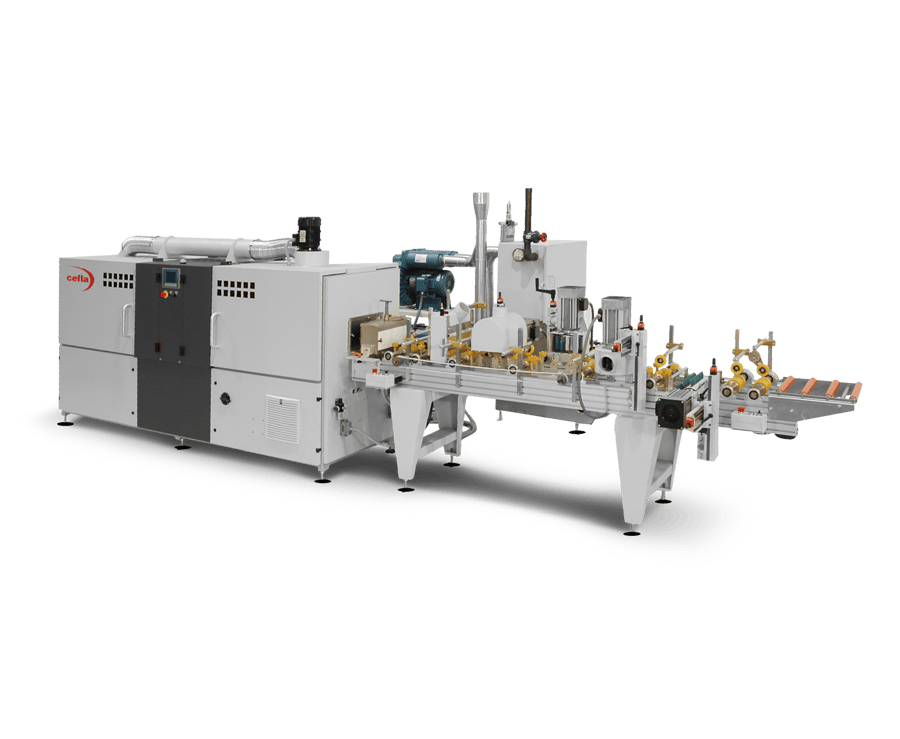

This finishing system integrates sanding, staining and drying into a single unit, perfect for water-based staining and priming applications.

The easily controlled vacuum system enhances grain without additional brush or hand wiping.

Description

Water-Based Stain or Primer Application and Drying

The CVR finishing system for profiles integrates sanding, coating and drying in one single and easy to use machine. A vacuum unit applies water-based stain or primer uniformly onto any profile or shape to produce a consistent and uniform coloring. This vacuum process enhances grain definition without the need for brush or hand wiping.

- Pre-Sanding/Denibbing: Upon request the in-feed conveyor can accommodate sanding heads with abrasive strip brushes for pre-sanding prior to coating application.

- Vacuum Application: The stain/primer is applied by a stainless steel vacuum coater system. It is possible to control the amount of applied product equally on up to 4 sides by simply increasing or decreasing the vacuum level in the application head.

- Short Wave IR drying: After exiting the vacuum head the profile enters an IR curing tunnel and passes under multiple high intensity IR emitters. The emitters irradiate the moulding 360° for perfect curing in just seconds. The freshly coated mouldings can then be stacked or processed immediately thereafter.

Characteristics

- Combines sanding, staining and curing into a single, easy-to-use machine

- Sanding: fully-controllable pre-sanding with abrasive strip brushes

- Four-side, adjustable, vacuum application

- Multi-lamp, infra-red curing in just seconds

- Frequency-controlled feed and brush motors allow tightly controlled production speeds

- Integrated PLCs for full production control

- Low VOC emissions | Reduced flammability

- Closed loop system offers maximum transfer efficiency and minimizes coating waste

- Low coatings costs

- Consistent results

- Small production footprint

Materials

Plastic

Metal

Wood

Fibre Cement