Focus On

Changing format, thickness, or type of material is no longer an issue: the J-PRINT SP Flatbed range is designed to quickly adapt to any production batch, ensuring maximum efficiency and eliminating long downtimes—thanks to its vacuum belt conveyor.

What is the J-PRINT SP Flatbed single pass printing machine?

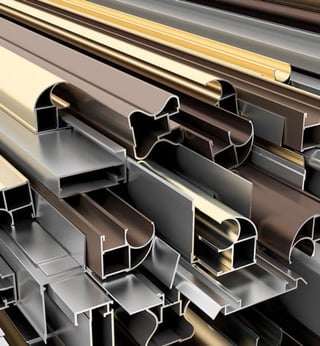

J-PRINT SP Flatbed is a single pass printing machine, ideal for flat surfaces and rigid materials. Thanks to its modular print bars, it can be tailored in size and configuration to meet any production need, delivering high-definition multicolor printing at very high speeds with UV inks and other specialty inks.

The TD (Texture Decoration) version integrates the printing of tactile relief effects, both positive and negative, to create structured and customized surfaces with next-generation realism and visual impact.

How does it work

Panels or “raw” pieces are placed on a vacuum belt conveyor, which transports them through the machine. The system automatically detects the position and applies the print sequence without interruptions or the need for manual adjustments.Industrial printheads accurately deposit inks or specialty fluids that, in the TD configuration, allow for the creation of three-dimensional textures/relief effects in perfect register (“Embossed In Register”, EIR).

Additional modules, such as UV-LED curing stations, ensure process continuity and safety.

Description

- Single pass flatbed technology for rigid materials

- Modularity: configurable print widths up to 1800 mm (larger upon request)

- Industrial-grade components for durability and non-stop production

- Drop on Demand (DOD) grayscale printheads

- Advanced ink circulation management

- Compatibility with UV and water-based inks

- Optional Texture Decoration (TD) for tactile relief/3D effects (positive/negative)

- Resolution up to 400 dpi

- Printing speed up to 50 m/min, depending on model and configuration

- Vacuum conveyor for materials of variable thickness (3 to 80 mm)

- Automatic parameter setting (thickness, format) and centralized management

Advantages

- Eliminates setup time: fast switch between batches and thicknesses

- High productivity, even for customized jobs

- Consistent multicolor quality and industrial repeatability

- Production of printed surfaces with advanced tactile effects

- Scalable system, easily integrated into line automation

- Reduced operational costs and faster order change management

- Ideal for furniture, composite materials, contract, interior design, and public or industrial spaces

Details