Focus On

Maximum flexibility: J-PRINT MP can adapt to different sizes and thicknesses of materials without lengthy setup times. Automation and the automatic adjustment system make management easy and efficient, even for custom batches or variable production.

What is the J-PRINT MP industrial digital printing machine?

J-PRINT MP is a multipass flatbed digital printing machine equipped with industrial printheads for UV inks, specifically developed for printing on flat surfaces and rigid materials. The robust working plate and the vacuum transport system (in stand-alone version) ensure precise positioning of the piece throughout the printing process. The machine can be configured with up to 8 color bars and up to 8 printheads per bar, delivering high-resolution, high-quality multicolor graphics.How does it work

The substrate is placed on the working plate, where industrial printheads deposit UV-curable (or other compatible) inks with multipass grayscale technology. The software system automatically manages all parameters and adjustments, including compensation for “missing nozzles” to ensure consistent quality.Printing is performed in multiple passes, with automatic cleaning of the printheads and advanced ink circuit management. The vacuum plate (for stand-alone use) keeps even large panels stable and always perfectly positioned.

Description

- Industrial multipass flatbed printing technology

- Maximum print width: 3000 mm

- Print length: starting from 2700 mm, expandable up to 6000 mm

- Printable thickness: standard from 3 to 80 mm (down to 0.1 mm in special stand-alone versions)

- Configuration: up to 8 color bars (4C is standard), up to 8 printheads per bar

- Number of ink channels: up to 8

- Inks: UV, water-based

- 2 UV-LED drying/curing modules

- Productivity: up to 400 m²/h (draft), 200 m²/h (quality mode)

- Automatic printhead cleaning system

- Proprietary software for automatic missing nozzle compensation

- Vacuum plate (stand-alone) or dedicated transport system (in-line)

- Load capacity: up to 50 kg/m² (stand-alone specification)

- Advanced automation

Advantages

- Simplifies the management of variable and custom productions, including small batches

- Optimizes production times and reduces downtime with smart automation

- Easily upgrades existing lines, boosting operational flexibility

- Minimizes maintenance thanks to automatic head cleaning systems

- Supports complex applications, ideal for architectural and interior design challenges

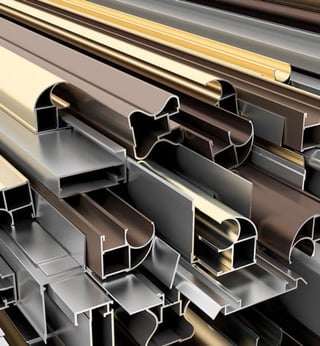

Materials

Plastic

Metal

Ceramic

Wood

Fibre Cement

Mineral Fibre