In recent years, the industrial cutting sector has undergone a profound technological evolution. Modern automated solutions enhance efficiency, quality, and safety, transforming every stage of decorative material processing. This guide explores the main developments, techniques, and results of the most advanced cutting technologies.

Overview of cutting technologies

Cutting technologies and industrial machines have evolved significantly over the years, replacing traditional manual methods with solutions increasingly geared towards automation.

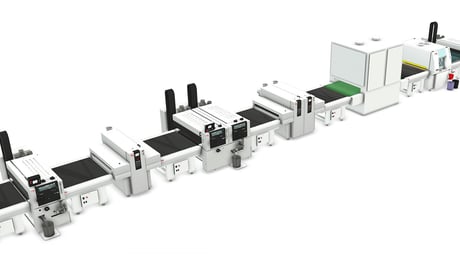

In this context, it is no exaggeration to say that today, especially in the transformation processes of decorative materials in reels, we are already in the era of 4.0 cutting machines: sophisticated integrated systems that use robotics to create advanced, modular lines. These are capable of greatly simplifying what is a delicate process.

These machines not only enable efficient and safe cutting, reducing human error and increasing productivity, but also help operators enhance operational effectiveness through continuous improvement.

We’re talking about the Internet of Things and Industry 4.0: integrating machines with dedicated software and sensors allows operators to monitor and control the cutting process in real time, ensuring a uniform, high-quality finish for various decorative applications.

Cutting techniques and operating modes

When it comes to optimising the cutting processes of decorative material reels, it is crucial to understand the specific techniques and operating modes involved.

Typically, the process starts with reel cutting, where the roll of material is divided into smaller sections using a saw. The term “saw” is actually reductive: a reel cutting machine uses highly precise mechanisms designed for the type of cut to be made and the materials to be separated, such as paper, PVC, and CPL (Continuous Pressure Laminate).

Just consider the types of blades needed for a paper cutting machine to understand the level of technology involved. There are two main cutting methods: direct cutting and reel-to-sheet cutting. Direct cutting separates the material directly from the roll, whereas reel-to-sheet cutting improves process efficiency by unrolling the reel, cutting it into sheets, and rewinding it.

This latter approach, though counter-intuitive, has a precise motivation: the winding mechanisms play a key role in maintaining consistent tension throughout the process, ensuring smooth and uniform cuts.

THE MOST ADVANCED FINISHING SOLUTIONS

An important factor: the quality of manual cutting

More specifically, with direct cutting, the saw cuts through the entire reel, including the cardboard core.

The second operation is handled by a machine that divides the reel through a process of unwinding and rewinding. In practice, the saw cuts the specific material, while the unwinding and rewinding machine is equipped with blades that separate various types of decorative materials in common use, including thermoplastic sheets.

Special components for excellent results

Good cutting quality is clearly the basis for successful material division. Needless to say, blade choice plays a critical role in achieving this.

Sharp rotary blades ensure effective cutting, but pose a high risk for the operator when positioned manually. Therefore, a solution that prevents this risk through automation should be considered.

Winding shafts with friction rings also contribute significantly to the process. They compensate for differences in the widths of rewound reels, ensuring proper sheet tensioning.

They also balance the negative effects that may arise from material inconsistencies on the parent reel. Then there are the safety systems. The most dangerous task for operators is blade placement, which must be as sharp as possible for the reasons mentioned above.

The ideal solution is to adopt systems that automate this step.

Advantages of automated solutions

Automated cutting solutions offer numerous advantages. One of the most significant is the substantial increase in productivity. Automated cutting technologies for PVC, paper, and CPL allow all material types to be managed with extreme precision, optimising operations based on the specific properties of semi-finished goods.

Striving for even better results means introducing an automatic tension adjustment system. This not only speeds up production times but also ensures consistent quality across all batches. Advanced line control features also improve operational safety: the risk of accidents from manual reel handling is drastically reduced.

Touchscreen controls also play a part, making machine operation more intuitive, allowing quick adjustments even for inexperienced users, and enabling real-time process monitoring.

Add to this the intelligence derived from integration—via network connectivity—with company management systems, and you take the final step into the Industrial Internet of Things: facilitating data exchange and boosting process automation unlocks the full potential of Industry 4.0, greatly improving overall operational flexibility.

This holistic approach means automated solutions not only reduce profile changeover time and enhance process safety, but also streamline job management, regardless of skilled labour availability.

Integration of lamination and coating processes

Naturally, cutting machines for decorative materials don’t operate in isolation—they’re an integral part of the overall production cycle.

These machines are designed to optimally support the transition from cutting to lamination, not only ensuring precision and safety in separation operations but also strengthening the production efficiency of the systems in which they’re used.

Plastic laminate reel production is an excellent example of how such systems work in synergy, generating high-quality output while reducing operational costs and material waste.

A key aspect of this approach is managing the coating and coating application procedures on the reel. By using advanced solutions to ensure uniform application over the entire reel surface, manufacturers can improve final product quality, ensuring durability and attractive aesthetics.

From theory to practice: Cefla Finishing’s solutions

Based on this awareness, Cefla Finishing has designed and developed fully integrated platforms, starting with its AutoCut, RSW, and EasyCut cutting machines—all capable of positioning their extremely sharp blades automatically.

Ensuring maximum precision, repeatability, and reliability, our solutions eliminate any risk to the operator. The machine control panel, available as a touchscreen, also allows connection to the company network, enabling transfer and storage of relevant production data.

This data forms a solid foundation for effective production management. Additionally, thanks to integration with company systems, process recipes can be prepared in the office using a standard PC. The operator at the machine simply selects the correct recipe to initiate a fully automated process.

AutoCut: when automation means precision

AutoCut is the ideal solution for companies needing to cut reels up to 1600 mm wide for coating processes. It ensures precise, finished work, thanks to the Automatic Slitter Positioning (ASP) system: an automatic positioning mechanism for the upper/lower blades and two in-line lasers to better align winding sleeves.

AutoCut features: - Applicable in numerous industrial sectors - Automatic positioning of the cutting disk - High flexibility thanks to multiple cutting systems - Remote and diameter-based automatic braking force control - Constant web speed and tension during winding - Easy blade replacement - Excellent accessibility with cantilevered winding shafts - Deionisation available

RSW: high-quality blades for excellent cutting

RSW is a robust machine capable of separating reels up to 1600 or 2200 mm wide. To ensure constant pulling force during unwinding and rewinding, the solution automatically controls and adjusts braking force. This guarantees ideal pulling tension regardless of reel width.

RSW features: - Remote and diameter-based automatic braking force control - Constant web speed - Reduced setup times thanks to quick-change tool kit, allowing tool changes while the machine is running - Two winding shafts - Stable steel structure with no oscillation - Residual strip suction system - High power for optimal winding results - Deionisation available

EasyCut: the versatile and user-friendly solution

Last but not least, EasyCut can be equipped with friction winding shafts ensuring reels of varying widths are rewound with consistent pulling tension.

The EasyCut cutting machine is the ideal choice for cross-cutting paper and sheets of PVC, PP, PE, PU, sandwich panels, laminates, certain fabrics, or metal foils, as well as veneered edges, ABS, melamine resin-coated edges, and other materials of various thicknesses.

Equipped with a practical control unit, it facilitates programming and is highly user-friendly.

EasyCut features: - High flexibility with different knife types - Supplied with 1 or 2 winding shafts - High drive power - High-quality blades for excellent cutting.

LOOKING FOR THE IDEAL SOLUTION FOR YOUR LAMINATION AND/OR COATING LINE?

.jpg?width=460&height=310&name=Articolo-OttimizzazioneProduzione-Social-LIN(ita).jpg)