Seamless batch-one production: Pontoni chooses Smartedge Agile

Dati di progetto

Customer:

Manufacturer of luxury kitchen components

Country:

Italy

Media Video:

Who’s the customer?

Founded nearly 60 years ago in Caldarola (Italy), Pontoni srl is a second-generation family company specializing in two complementary business lines: kitchen sector: fronts, shelves and side panels for Italy’s leading kitchen manufacturers, and luxury interiors: bespoke, turnkey furniture for top Italian and international brands—delivered complete with premium materials such as marble, metals and leather, via a trusted network of partners.

Today Pontoni counts ~60 people, operates strictly as an OEM supplier, and is recognised for ISO-driven quality and confidentiality across client programs. Final destinations for its luxury projects span the Middle East, China and the USA.

The challenge

Pontoni’s continuous growth in both kitchen components and luxury interior projects brought increasing complexity to production. The company needed to manage a wide variety of panel sizes and thicknesses while ensuring top-tier quality standards required by international brands. At the same time, sustainability objectives had to be met through reduced energy use and water-based finishing processes, without compromising aesthetics or durability.

Another crucial point was efficiency: the production flow, from cutting to finishing and final assembly, required optimization and traceability. Finally, Pontoni needed to rely on prompt, expert service and support to minimise downtime and keep production lines running smoothly.

The Cefla Finishing solution

The collaboration between Pontoni and Cefla Finishing is rooted in a partnership of more than four decades. The first breakthrough came in 1989 with the installation of a prototype robotised spray line that replaced manual spraying, delivering repeatable quality and higher productivity. In the early 2000s, two more Cefla lines were integrated: one automatic finishing line and an advanced robotic spray solution, both of which ensured consistent results and higher throughput.

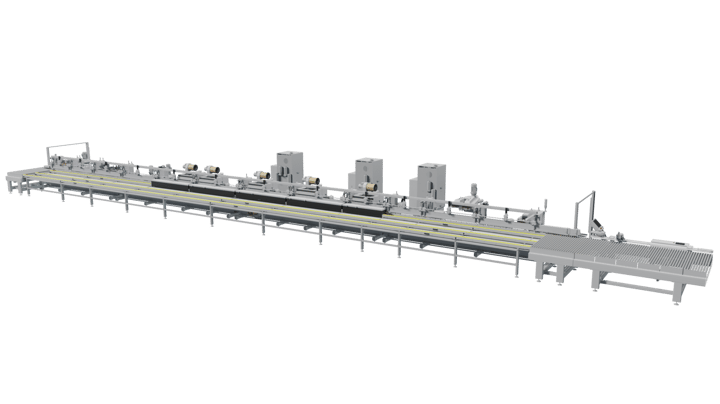

Today, the focus is on Smartedge Agile, a state-of-the-art vacuum application and sanding system that stands out for its ability to automatically adapt to different thicknesses, eliminate set-up times, and reduce material waste.

This solution aligns with Pontoni’s production model, which demands flexibility to cope with batches presenting a significant variety of panels and the use of sustainable, water-based lacquers. Combined with operator training and integrated remote assistance, Cefla’s technology has helped Pontoni achieve a seamless digital workflow where every panel is tracked by barcode from cutting through to final packaging

Results

The adoption of Cefla Finishing technologies has allowed Pontoni to significantly increase its production capacity while maintaining rigorous quality and confidentiality standards. Automation has made changeovers quicker and minimised errors, while Smartedge has provided a decisive improvement in edge processing, reducing preparation times and ensuring consistent quality across varying panel types.

Water-based finishing processes, combined with energy-efficient machines and a 500 kW photovoltaic system, have reduced both operating costs and environmental impact. Finally, thanks to reliable technical support and remote diagnostics, Pontoni can count on stable uptime and rapid interventions when needed, securing both productivity and peace of mind.

Value to the business

Cefla Finishing’s contribution is both technological and relational. Automated edge-finishing solutions give Pontoni the flexibility to handle a demanding, complex portfolio while ensuring ongoing product quality. The long-term partnership—training, proactive maintenance and swift assistance—translates into reliable capacity, predictable lead times, and confidence to take on complex luxury projects destined to distant markets. In short: flexibility with consistency, engineered for premium results.

The value of Cefla Finishing’s people

Pontoni highlights Cefla’s 360° support: knowledgeable technicians, effective remote troubleshooting, and—when needed—on-site service typically within 48 hours. Over time, the working relationship has grown into a trusted, familiar team dynamic that eases day-to-day problem solving and accelerates continuous improvement.

Future-focused, together

With Industry 4.0 systems already in place (end-to-end barcode traceability) and a clear path toward Industry 5.0, Pontoni is reaping the benefits of automation and scaling Smartedge Agile across programs. The roadmap stays consistent: premium quality, sustainability, and flexible finishing—backed by Cefla’s technology and people.

“The relationship with Cefla doesn’t stop at the moment of sale; the after-sales service never leaves you on your own.”

Project Gallery

No video selected

Select a video type in the sidebar.