Over many years, we have witnessed several requirements to coat products that have a distinctly three-dimensional shape, a factor which frequently makes them hard to manage on overhead spray coating lines. Most times, the solution used by the customer remains manual coating with all the drawbacks involved.

Manual operations are heavily dependent on the skills of the person carrying out the task. There can be significant variations in the quality of the application and productivity will never be consistent either. Moving pieces around manually causes physical fatigue and can even pose major problems if the pieces are heavy or cumbersome.

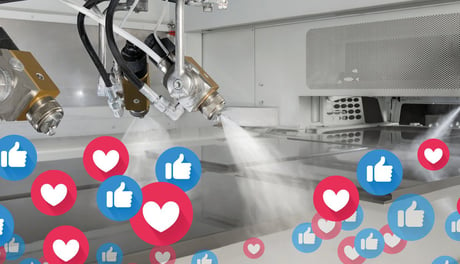

Automation of the process (from handling to coating and drying) will greatly improve quality, production efficiency and working conditions for employees. However, if an overhead line is out of the question, the solution we have implemented year after year, product after product, has always revolutionised the process and the results.

Coating process: easier with floor-mounted lines

Think of an operator moving around a product to coat it. The person collected it from somewhere, positioned it and then moved it on to the next stage in the process: drying.

Now think of a spraying robot coating a product as it moves and rotates slowly on an automatic, floor-mounted line, continuing to the next stage in the process: drying.

Which of these two solutions appeals most? Manual or automatic?

The benefits of an automatic solution

An automatic line transforms many aspects of the company’s finishing process. These are a few of the most evident advantages:

- improved coating consistency and finished product quality

- improved production efficiency and shorter lead times

- reduced lacquer consumption and related costs

- high degree of coating flexibility

- minimal use of manual labour for coating and handling operations

Our floor-mounted coating solutions: noteworthy examples

As there are many cases where a customised line can be implemented successfully to minimise manual labour and improve quality, we have accomplished a number of lines which are described in greater detail on dedicated web pages. For example:

- motorcycle helmets

- sofa legs

- plastic flower pots

- rifle butts

- pianos and grand pianos

- shoe trees

- coffins and funeral caskets

- sidings

- cajones (percussion instruments)

Use our expertise to solve your needs

Cefla Finishing has years of experience building automated, floor-mounted coating lines. Each product is different and each coating or drying requirement is specific to product and substrate. This is why standard solutions are not available, but with a track record of similar solutions, we will be able to design the best line in less time.

Contact us and our team will examine your requirement.